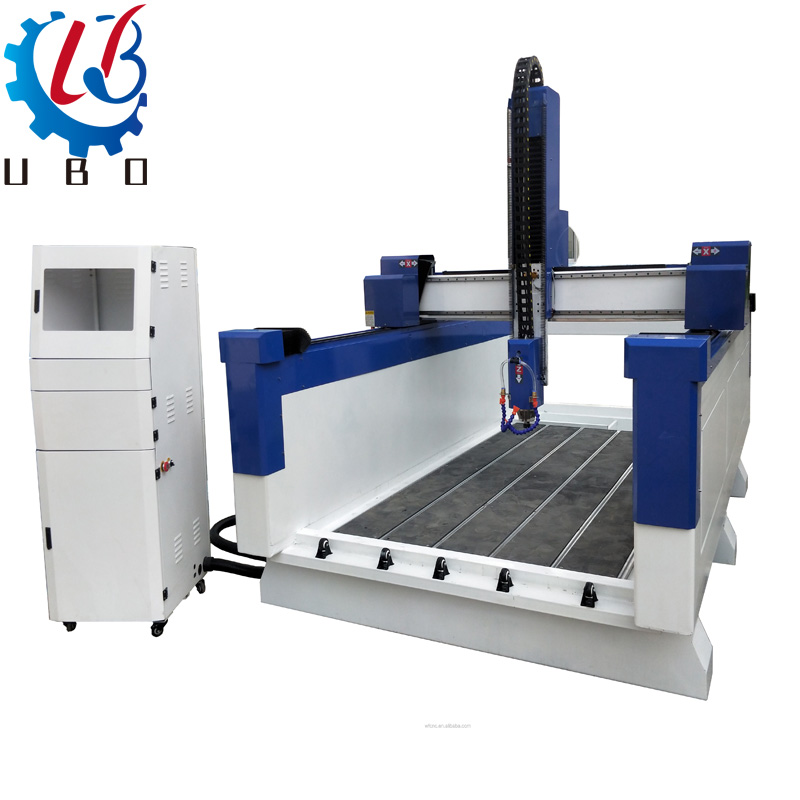

Reasonable price Automatic Edge Banding Machine - marble granite engraving machine 1325 stone cnc router sculpture machine stone cnc marble Engraving Machine – UBO

Reasonable price Automatic Edge Banding Machine - marble granite engraving machine 1325 stone cnc router sculpture machine stone cnc marble Engraving Machine – UBO Detail:

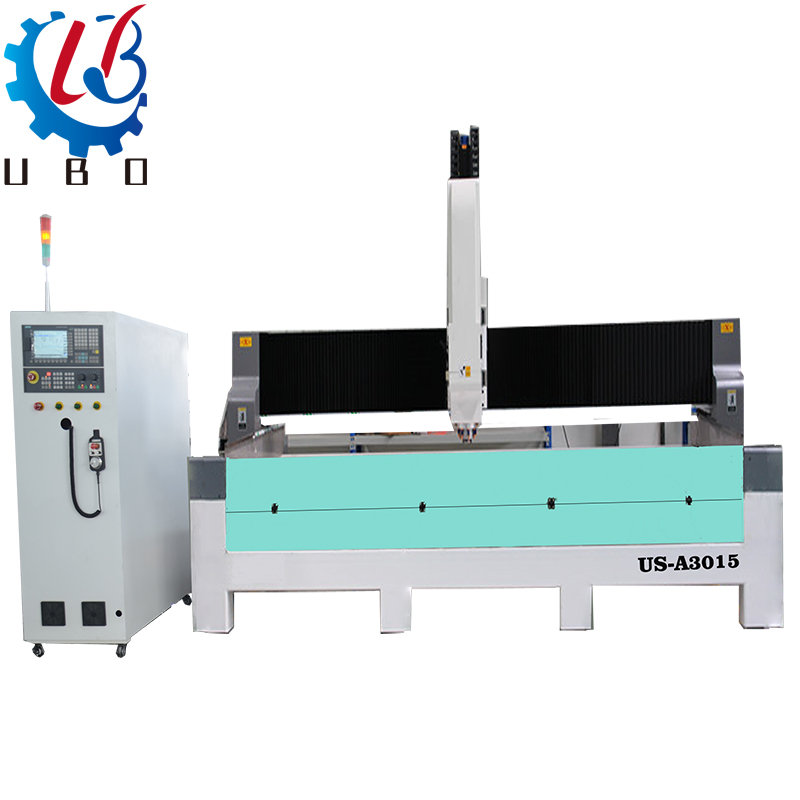

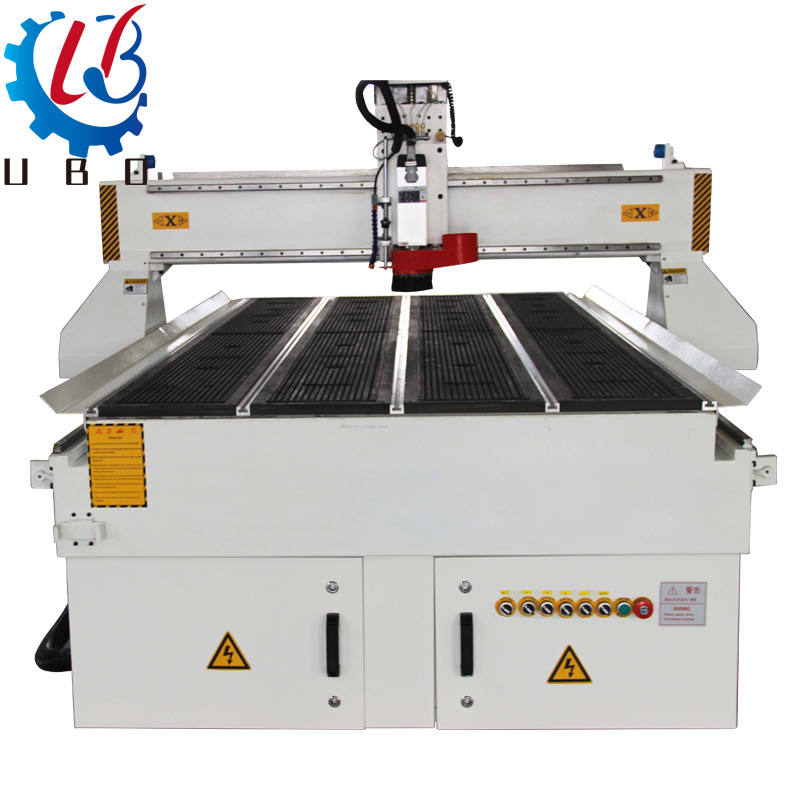

1.Heavy duty whole steel welded structure ,could load heavy stone on the table.

2. T-Slot table with universal beam steel ,prolong clamp device to hold all type of stone still.

3. Loading wheel in front of table ,easy to load, stainless steel water tanks keep all the water recycle inside.

4. DSP portable DSP controller or Computer based controller, friendly to all type of CAD/CAM software which could create G-code.

5. High powerful 5.5-7.5kw water cooling spindle with constant torque, Water cooling device to protect cutting bits.

6. All axis with covers to protect the rack and pinion from dust and water splash.

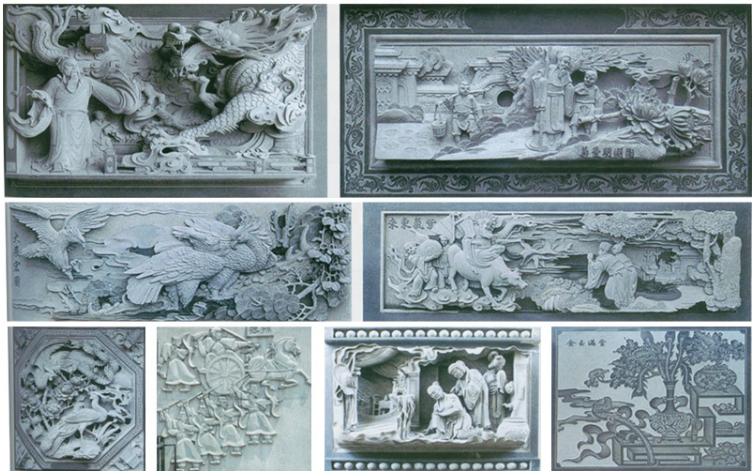

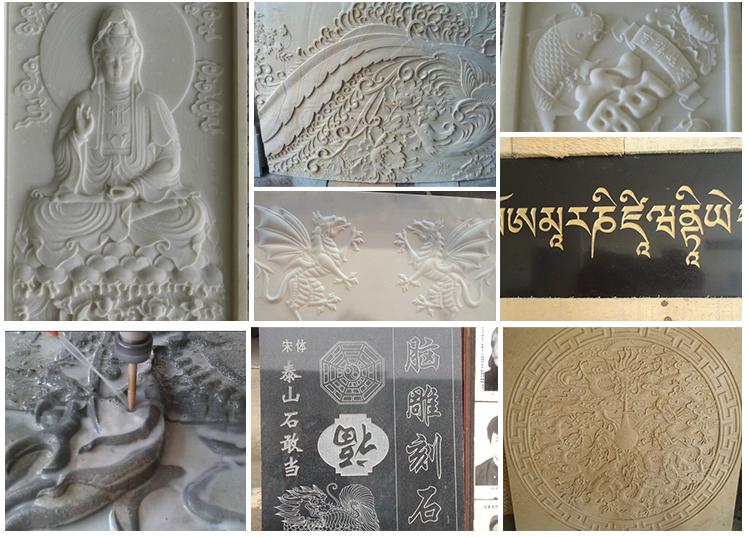

Suitable for cabinets artificial stone, quartz stone countertops and sink, tea tray caving, European style edging, and other heterosexual stone, ceramics, glass and ceramic stone drilling sanding, edge down, carving. 3D and 3D application including kitchen tops, shower plates, tombstones, bas-reliefs, grooving and lettering.

| Model | US-1325H |

| Working size | 1300*2500*600mm |

| X, Y, Z axis Traveling positioning accuracy | ±0.03 |

| X, Y, Z axis Reposition accuracy | ±0.02mm |

| Transmission system | X, Y axis HIWIN Linear Rail + Helical Gear Rack |

| Z axis HIWN Linear Rail + TBI ballscrew | |

| Driving system | Stepper motor + Leadshine drivers |

| Max working speed | 18000mm/min |

| Spindle | 5.5KW water cooling spindle |

| Spindle revolving speed | 0-24000rpm |

| Inverter | Folinn |

| Command language | G code |

| Control system | DSP A11 |

| Support Software | Type3/Artcam/Artcut/Ucancam etc |

| Running environment temperature | 0-45 centigrade |

| Relative humidity | 30%-75% |

| Working voltage | 380V, 50/60Hz |

| Weight | 1500kg |

| Machine size | 3300*2150*1850mm |

Packing:

1.The innermost layer is EPE pearl cotton film package.

2.The middle layer is wrapping up with environmental protection material .

3.And the outermost layer is winding up with PE stretch film.

4.They’re very environmentally friendly.

5.If you need a wooden box, we will make a wooden box.

Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

*More than 95% of the timely response rate, timely response to customer questions

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* Use online contact methods such as skype whatsapp facebook to provide online services to customers.

Q1. How can I get the machine ,how to order ?

After we confirm all details ,then You can pay 30% deposit according the Proforma invoice, then we will start to make production. Once the machine is ready , we will send pictures and video to you, and then you can finish the balance payment. Finally, we will pack machine and arrange delivery for you as soon as possible.

Q2. How long time will need for my machine to delivery?

For standard machines, it would be about 7-10 days. For customized machines according to your specific requirements, it would be about 15-20 working days.

Q3. If some problems happened during warranty period, how you do service?

We will supply free parts in machine warranty period if machine have some problem. While we

also supply free after-service forever,so any doubts,just let us know,we will give you solutions in 30 minutes.

Q4. How to use the machine after receving the machine

Firstly , when you got machine , you need to contact with us ,our engineer will together with your to deal with it ,secondly ,we send user manuals and CD to you before you get the machine ,Thirdly Our professional technician online teach you until you can use it well by yourself.

Product detail pictures:

Related Product Guide:

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for Reasonable price Automatic Edge Banding Machine - marble granite engraving machine 1325 stone cnc router sculpture machine stone cnc marble Engraving Machine – UBO , The product will supply to all over the world, such as: Greek, Luxembourg, Netherlands, We've been always creating new technology to streamline the production, and give products with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We are going to present our best service to satisfy all your needs! Remember to contact us right away!

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!