raycus 1000w fiber laser cutting machine 1390 / laser Cutter Sheet Metal 1313

(1). mini model ,but widely used ,bigger functions.

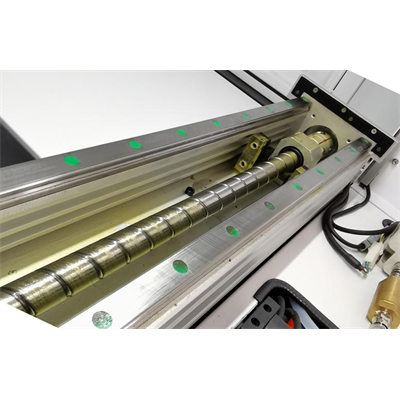

(2).Gantry double-drive structure,with imported Germany rack & gear transmission system, which improves the production efficiency.

(3).Heavy Thick plate welding bed design, after stress relief annealing, the structure is more stable, equipped with partition dust removal, energy saving and environmental protection

(4). High precision, fast speed, narrow slit, minimum heat affected zone, smooth cut surface and no burr.

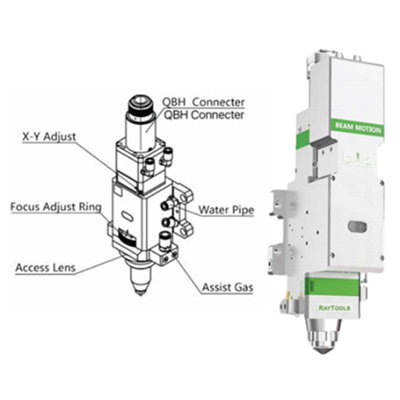

(5). The laser cutting head does not come into contact with the surface of the material and does not scratch the workpiece.

(6). The slit is the narrowest, the heat affected zone is the smallest, the local deformation of the workpiece is very small, and there is no mechanical deformation.

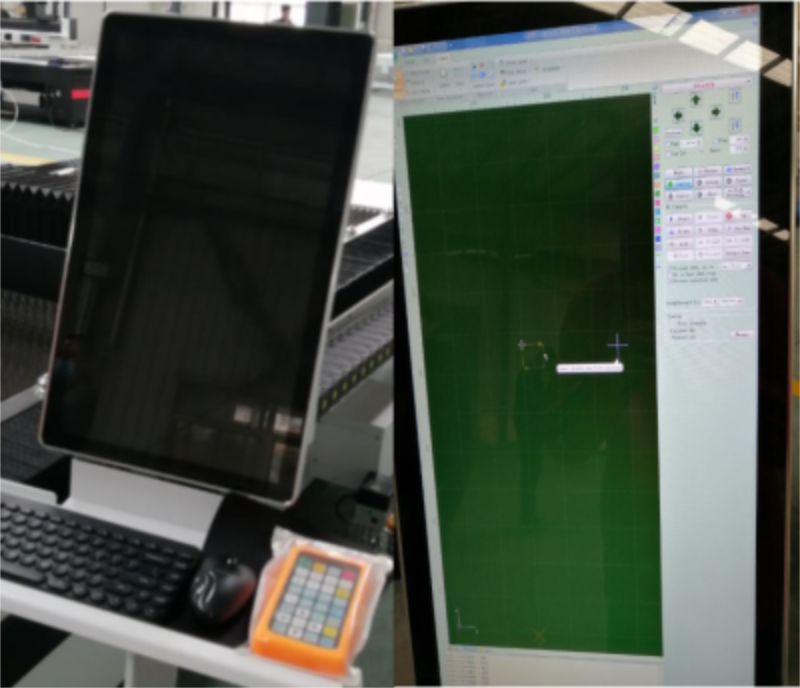

(7). Can support multiple formats of input, with better compatibility

Applicable materials

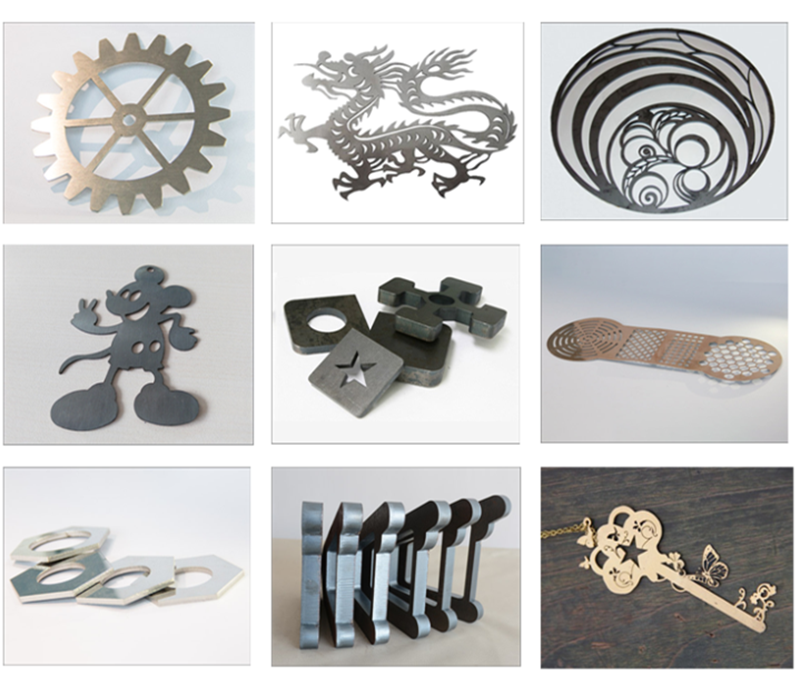

Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet,Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet,Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Application Industries

Fiber Laser Cutting Machine is widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters,Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & CabinetsProcessing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts,Nameplates, etc

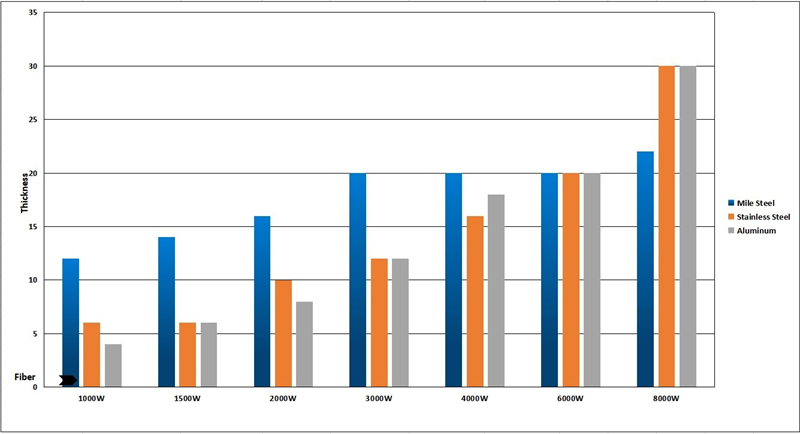

Cutting ability

| Model | UF-C1390 | UF-C1313 |

| working area | 1300x90mm | 1300x1300mm |

| Laser Power | 500w/750w/1000/1500W/2000W | |

| Laser wave length | 1064nm | |

| Transmission system | High quality ball screw transmission | |

| X.Y axis accuracy | ±0.01mm | |

| X.Y axis repeat accuracy | ±0.01mm | |

| max moving speed | 40m/min | |

| Max cutting speed | 1--50m/min(according to metal material and laser power) | |

| Cutting thickness | According cutting thickness | |

| Application Material | Metal sheet Iron/CS/SS/Aluminum/Copper and all kinds metal |

|

| Advantages | >Excellent beam quality >Simple , compact, electrically and optically efficient >Compatibly powerful and reliable >Maintenance free >multilingual, more than 11 foreign languages >3 years warranty . |

|

1.Pre-Sales Service:

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

2.After-Sales Service:

*Three-year warranty on the whole machine accessories if the machine parts have any problems,we can change the old machine parts to new ones free.

*Exceed three years warranty period if the machine parts have any problems,we can offer new machine parts with cost price and you also should pay all the shipping cost.

*We offer 24 hours technical support by call,email.

*Our technician can give you remote guide online(Skype/MSN/What's app/viber/Tel/Etc) if you have any question.

*Machine has been adjusted before delivery,operation disk is included in the delivery.If there is any other questions,pls kindly tell me.

*We have manual instruction and CD (Guiding Videos) for software Installation,operation and machine's using and maintenance.

3.UBO CNC supply free technical training for all customers all over the world until the workers from buyer can operate the machine normally and individually. Mainly training are as follow:

*Training for Control software operation.

*Training for normatively turning on/off operation of the machine.

*Instruction of technical parameters, as well as their setting ranges.

*Basic daily cleaning and maintenance for the machine.

*Solutions for common hardware problems.

*Training for other questions and technical suggestions during daily production.

4.Training can be processed in the following ways:

*Workers of customers can come to our factory to get the most professional hand-by-hand training.

*We can send engineers to customers' country and do training for workers in customers' target factory.However,tickets and daily consumption like food and accommodation should be afforded by customers.

*Remote training through Internet tools like Team-viewer,Skype and other instant communication softwares.

You can tell us your working material, detail work by picture or vedio so that we can judge whether our machine can meet your need or not. Then we can give you the best model depends on our experience.

We will send you manual and guide vedio in English, it can teach you how to operate the machine. If you still can not learn how to use it, we can help you by "Teamviewer" online help software.Or we can talk by phone, email or other contact ways.

Yes, we can supply many models . (130*250cm,150*300cm,200*300cm...) , and laser wattage (ranging from 500 watts to 5000 watts) If you'd like help determining which laser is right for your application or receive pricing information.

The machine has one year guarantee. If it breaks down, generally speaking, our technician will figure out what the problem may be, according to client s feedback. Parts except for consumable parts will be replaced for free if the problems are caused by quality fault.

After shipment, we'll send all original documents to you by email or by DHL, including Packing List, Commercial Invoice, B/L, and other certificates as required by clients.

For standard machines, it would be 5-10days; For non-standard machines and customized machines according to client s specific requirements, it would be 15 to 30 days.

Telegraphic Transfer(T/T) to our official company bank account or Western Union(WU) or via alibaba trade insurance order payment

Yes, For EXW price, It is costly to pick up machine from our factory ,we could send machines to any Chinese sea port warehouse by add some domestic shipping cost.

For FOB or CIF price, we will arrange shipment for you.

We could send free parts to you in warranty period if machines have any problem under "normal use".

1)Your metal or non-metal material size. Because in our factory, we have different models according to working area.

2)Your materials. Metal/Acrylic/plywood/MDF?

3)You want to engrave or cut?

If cut, could you tell me your cutting thickness? Because different cutting thickness need different laser tube power and laser power supplier.