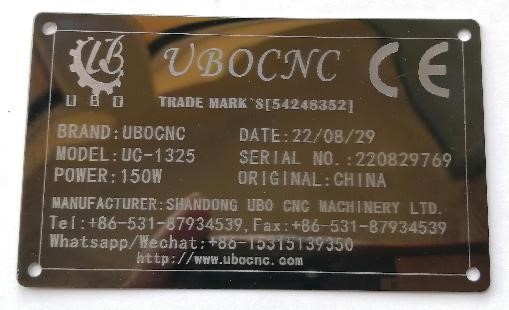

PriceList for Mini Co2 Laser Engraving Machine - CO2 laser cutting machine Acrylic CO2 Laser Cutting/Laser Engraving Machine – UBO

PriceList for Mini Co2 Laser Engraving Machine - CO2 laser cutting machine Acrylic CO2 Laser Cutting/Laser Engraving Machine – UBO Detail:

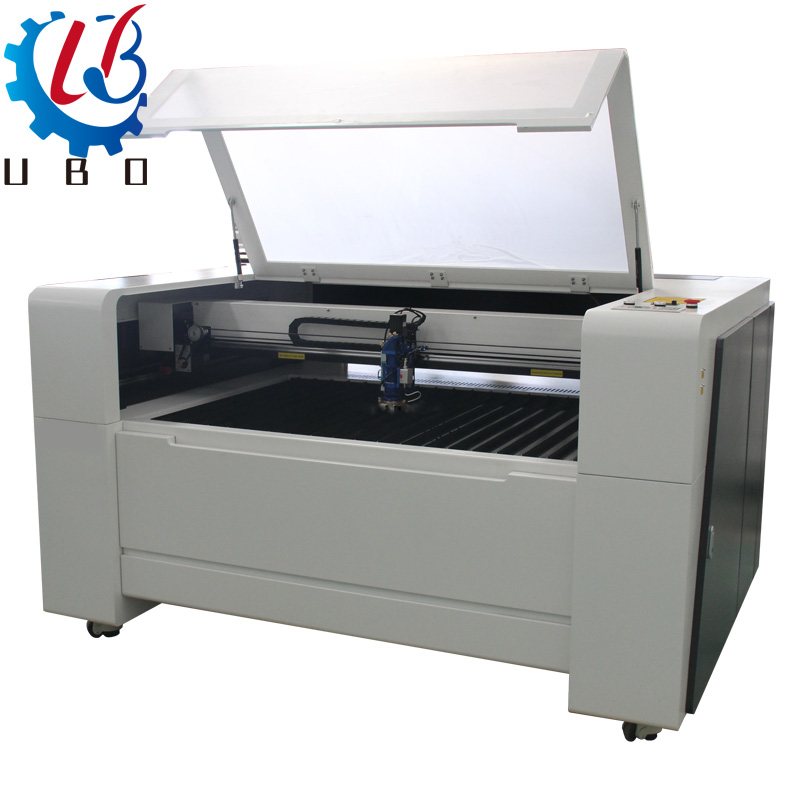

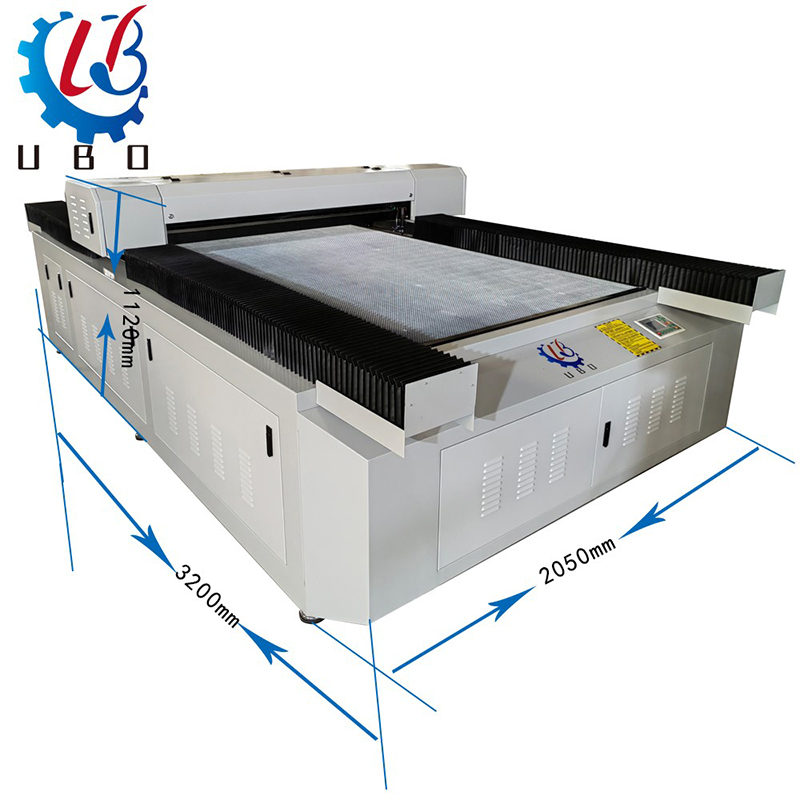

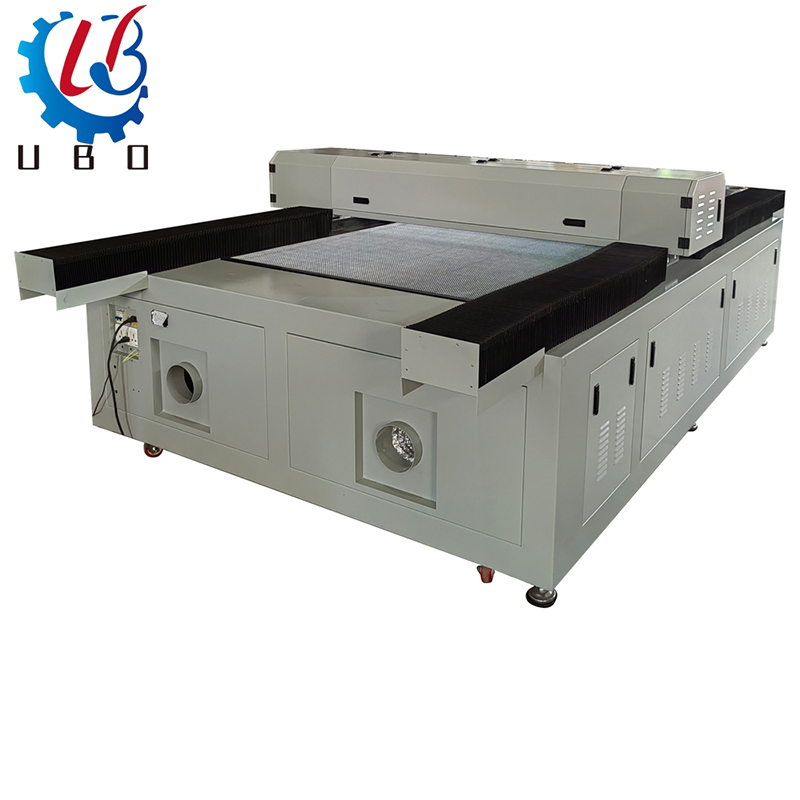

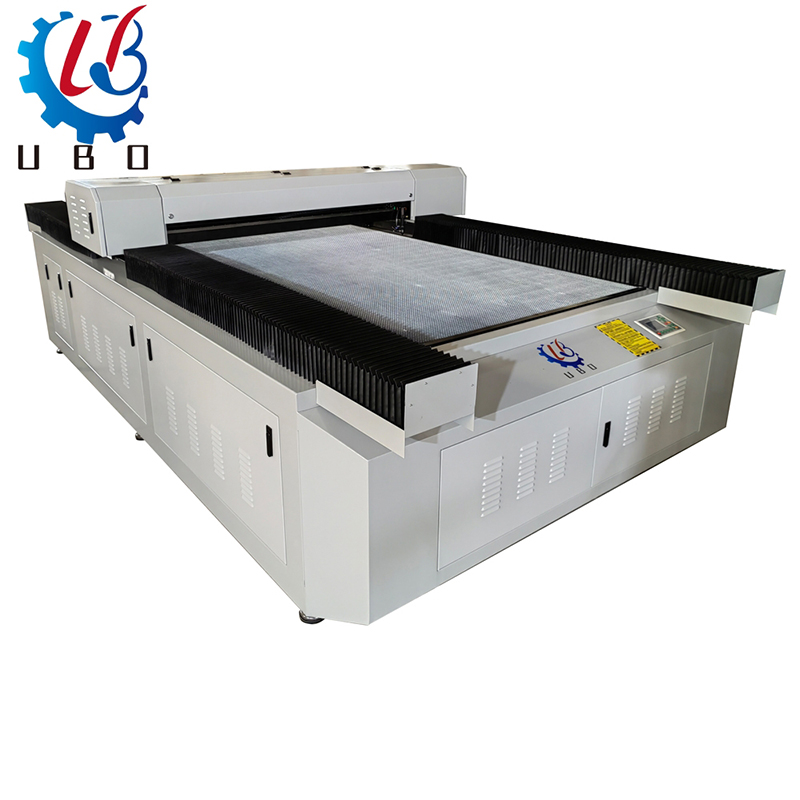

UBO Acrylic Laser Cutting Machine UC-1325 is one type of CNC Laser Machine which is designed mainly for engraving and cutting work on material such as Acrylic, clothes, Fabric, papers, wood. Machine normally equipped with 60-300W laser tubes.The honeycomb or blade type holding table easy for good for heat radiation, Water chiller keeps the laser tube at normal temperature. Dust collecting device could suck all the smoke away during work. Our Acrylic Laser Cutting Machine for could cut up to 25 mm thickness acrylic sheet into different shape as designing request. Meanwhile ,Machine table could built to be automatic up and down with a rotary clamp attached for the cylinder material. Except for Acrylic, our Acrylic CNC Laser Engraving and Cutting Machine UC-1390 is also could be used for non-metal cutting such as Leather, Rubber, Plastic, shoes, clothes etc .

1. Hermetic and Detached CO2 Glass Laser Tube

More than 10000h long lifetime,we can choose the suitable laser tube power according to different processing material thickness.

2. Honeycomb Working Table For Your Option

Especially for fabric engraving which can absorb the fabric firmly.

3. Thicken Strip Working Table For Your Option

Specially used for cutting and for heavy and hard products such as acrylic, PVC board cutting.

4. Customized Double Working Table

Design for your different material engraving and cutting requirements.

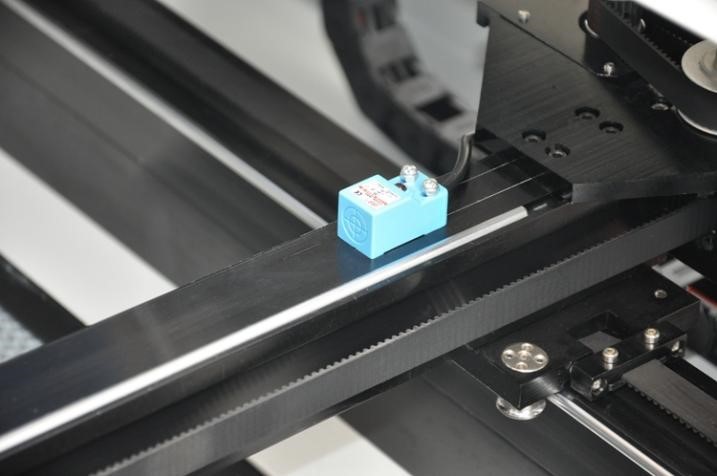

5. Taiwan Imported high precision Linear Guide Rail and Ball Screw Rod

High speed and accuracy with lower noise & long life span. Helps laser head move smoothly and laser beam reflect with high accuracy.

6. Water Chiller with Alarm Protection

CW-5200 Water Chiller with temperature display, which can avoid over burning, to protect the water circulation from electricity-off.

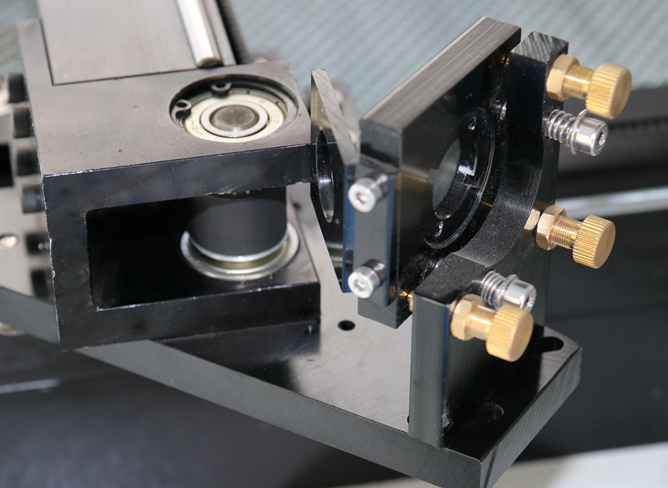

7.Reflector Mirror Holder

Focal length adjusting Parts easy to find the center of the lens and find the right focal distance.

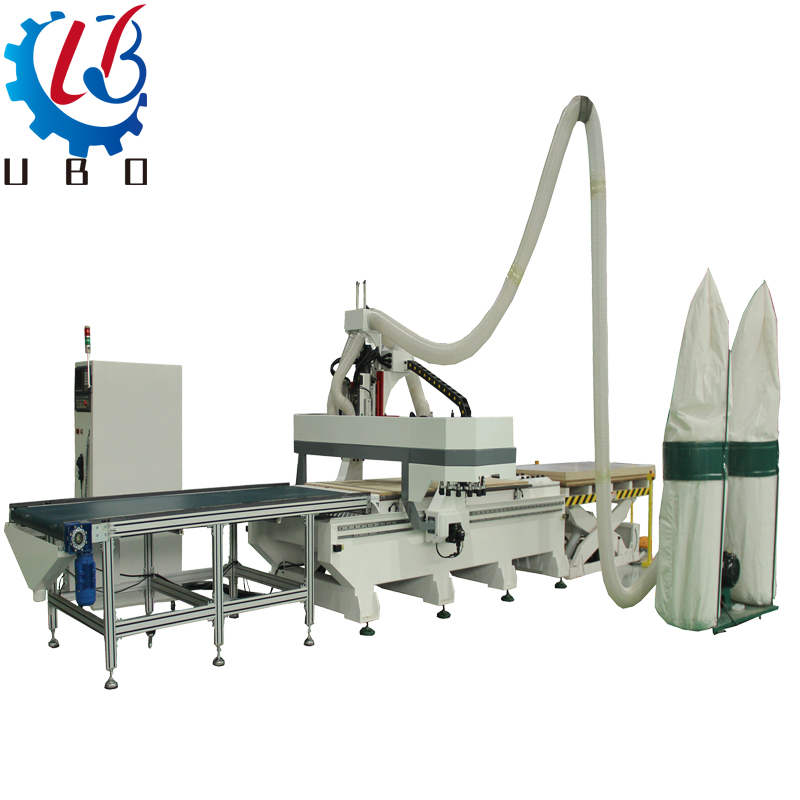

1)Foam processing of automotive stamping dies, casting of wood molds, automotive interiors, engineering plastic materials, and various non-metal processing

2) Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

3) Wood mold processing center: Casting wood mold, automotive inspection tool processing, automotive interiors, engineering plastic materials and other non-metallic processing.

|

Item |

Parameter |

|

Model |

UC-1325 |

|

Processing area |

1300mm*2500mm |

|

Laser power |

EFR /RECI 150W CO2 Source |

|

Laser type |

Sealed Co2 glass laser tube |

|

Cooling mode |

CW5200 Water cooling and protection system |

|

Resetting positioning accuracy |

±0.05mm |

|

Compatible Software |

laser work CorelDraw, AutoCAD, Photoshop |

|

Engraving speed |

1-10000mm/min |

|

Cutting speed |

1-3000mm/min |

|

Cutting thickness |

0-30 mm acrylic (others determined by materials) |

|

Resolution ratio |

≤0.0125mm |

|

Interface: |

USB |

|

Minimum shaping character |

letter 0.8mm, Chinese 2mm |

|

Controller |

RD control system |

|

Support graphic format |

DST, PLT, BMP, DXF etc |

|

Gross power |

1800W |

|

Driving mode |

DC0.8A 24V stepper motor |

|

Cooling mode |

Circulation water cooling |

|

Working voltage |

AC 220V±10%, 50 Hz |

|

Operating temperature |

0-45C |

|

Operating humidity |

5-95% |

|

Driving system |

stepper |

|

Packing |

wooden box |

|

Guarantee time |

2 years, laser tube 10 months |

|

Operation |

Video to tell customer how to operate the machine |

|

Net weight |

550KGS before package |

|

Gross weight |

630KGS after package |

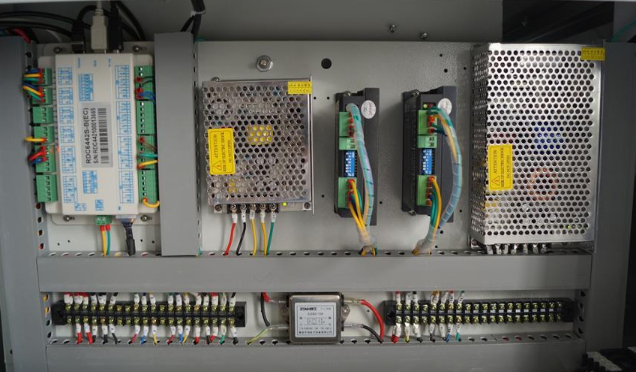

1.DSP control panel

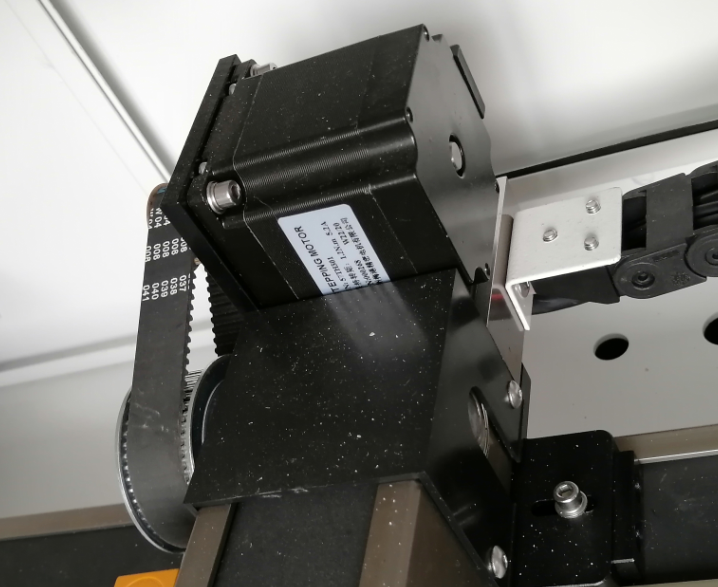

2.Three phase stepper (generate high speed work and precision location)

3.High quality 150w laser tube (the warranty of laser tube 10 months ,the working hours more than 10000 hours)

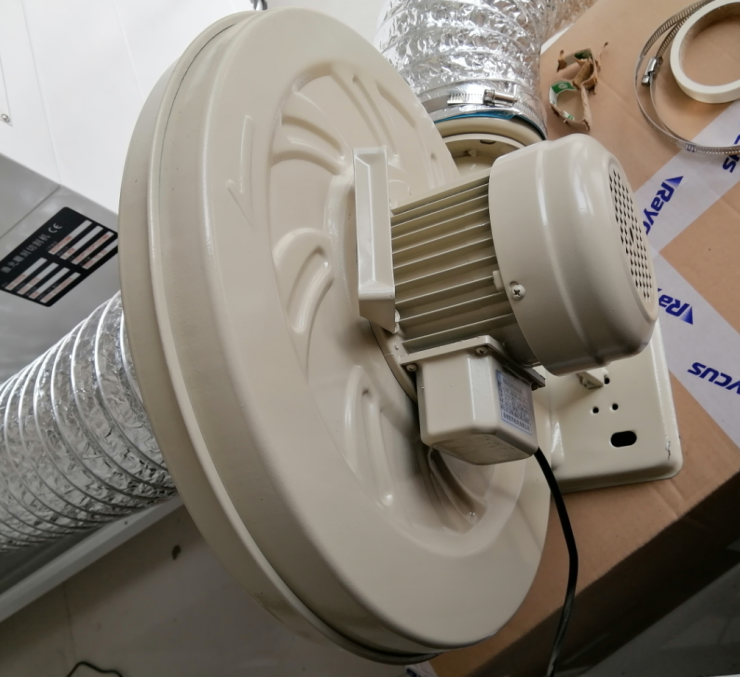

4.Exhaust fan

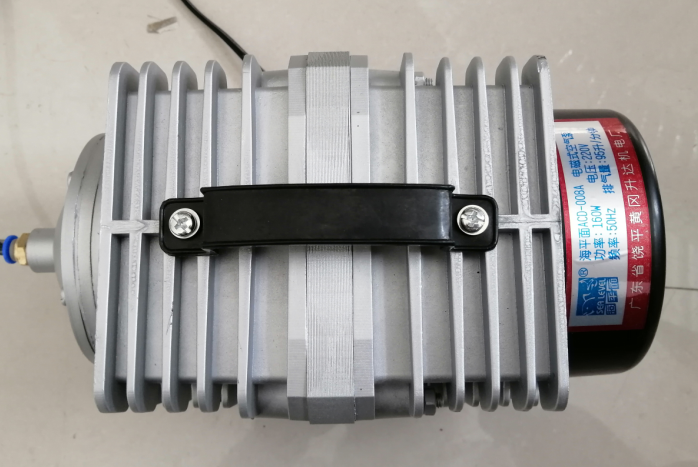

5.Air pump

6.Cooling system

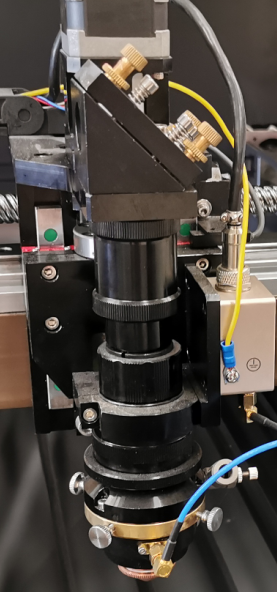

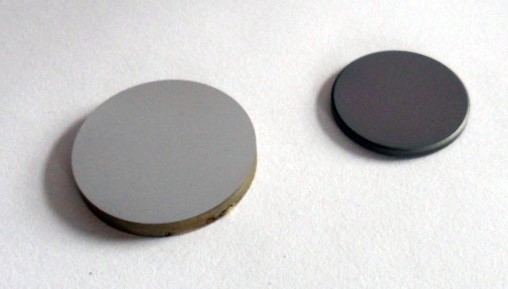

7.Mirrors lens

8.Rdcam card

9.Leadshine stepper driver

10.Hiwin/PMI linear guide from Taiwan

11.Belt transmit

12.wood package refer to sea transmit

13.Video to tell customer how to operate the machine

14.Auto focus

15.The warranty of total machine is 2 years but not include laser tube, the warranty of laser tube is 10 months.

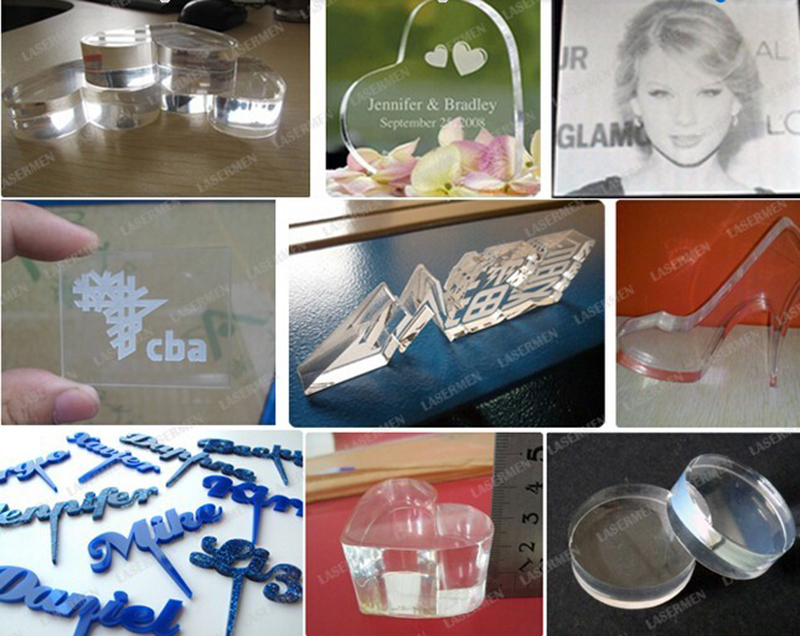

UC-1390 laser engraving machine is used specially for the nonmetal art crafts, gifts and the engraving of bamboo products. The mechanical structure is strong and stable, making the machine to run at high precision. The electrical ability is stable, the engraving speed is high, and the precision is high.

The machine can engrave beautiful pictures, peoples’ photos on the surface of many materials of different size of materials (marble, black or colored acrylic etc). It can also engrave many signs, marks. It is a machine with high cost performance.

materials:

Non-metal materials such as acrylic, double color board, Plexiglas, acrylic,

Common glass, bamboo and wood, rubber, marble, granite and tiles, leather cloth etc.

Thin Metal materials such as stainless steel, carbon steel

industries:

Advertising industry, Billboards, artistic gifts, crystal ornaments, paper-cut, bamboo

and wooden product, garment and leather, embroidery, decoration and upholster industry.

6.1 Equipment installation and commissioning

6.11 UBOCNC will provide the user a CD to study the machine installation and commissioning. If you have any problem, please contact us by call or online at any time.

6.2 Training

6.21 Free of charge for customers with after-sales training.

6.22 Training people to have certain qualifications and relevant knowledge, the supplier will do training for programming, operations, processing and maintenance training, trainees should be fixed, and study hard.

6.3 After-sales service

6.31 Two years warranty,during warranty can be provide parts for free.

6.32 Engineers available to service machinery overseas.

6.33 Use online contact methods such as wechat/ teamviewer/skype/whatsapp etc to provide online services to customers.

1. service before sales: our sales will communicate with you to know your requirements about the cnc router specification and what kind of work you will do, then we will offer our best solution for you. So that it can confirm each customer get their real needed machine.

2. service during production: we will send photos during manufacturing, so customers can know more details about the procession of making their machines and give their suggestions.

3. service before shipping: we will take photos and confirm with customers the specifications of their orders to avoid the mistake of wrong making machines.

4. service after shipping: we will write to customers in time when the machine departs, so customers can make enough preparation for the machine.

5. service after arrival: we will confirm with customers if machine is in good condition, and see if there is any spare part missing.

6. service of teaching: there are some manual and videos about how to use machine. If some customers have further question about it, we have professional technician to help install and teach how to use through Skype, calling, video, mail or remote control, etc.

7. service of warranty: we offer 12 month warranty for whole machine. If any fault of the machine parts within warranty period, we will replace it for free.

8. service in long-term: we hope every customer can use our machine easily and enjoy using it. If customers have any problems of machine in 3 or more years, please contact us freely.

Q1. How to get the most suitable machine and best price

Please tell us the material you want to engrave or cut? Max size and thickness?

Q2. If we don’t know how to use the machine,can you teach us?

Yes, we will, English manual and video will come along with the machine. You also can contact our service team if you need any help during use our machines.

Q3.How about your after-sales service?

we offer you 24 hours service by phone, Skype or Whatsapp.

Q4. Quality Control:

The whole production procedure will be under regular inspection and strict quality control. The

complete machine will be tested to make sure they can work very well before being out of factory.

Our machine passed CE Certificate, meet European and American standard, were exported to more than 100 Countries.

Q5. How we pay you?

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

Product detail pictures:

Related Product Guide:

We also offer product sourcing and flight consolidation services. We have our own factory and sourcing office. We can provide you with almost every type of product related to our product range for PriceList for Mini Co2 Laser Engraving Machine - CO2 laser cutting machine Acrylic CO2 Laser Cutting/Laser Engraving Machine – UBO , The product will supply to all over the world, such as: Wellington, Bhutan, Greece, Our stock have valued 8 million dollar , you can find the competitive parts within short delivery time. Our company is not only your partner in business, but also our company is your assistant in the coming corporation.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.