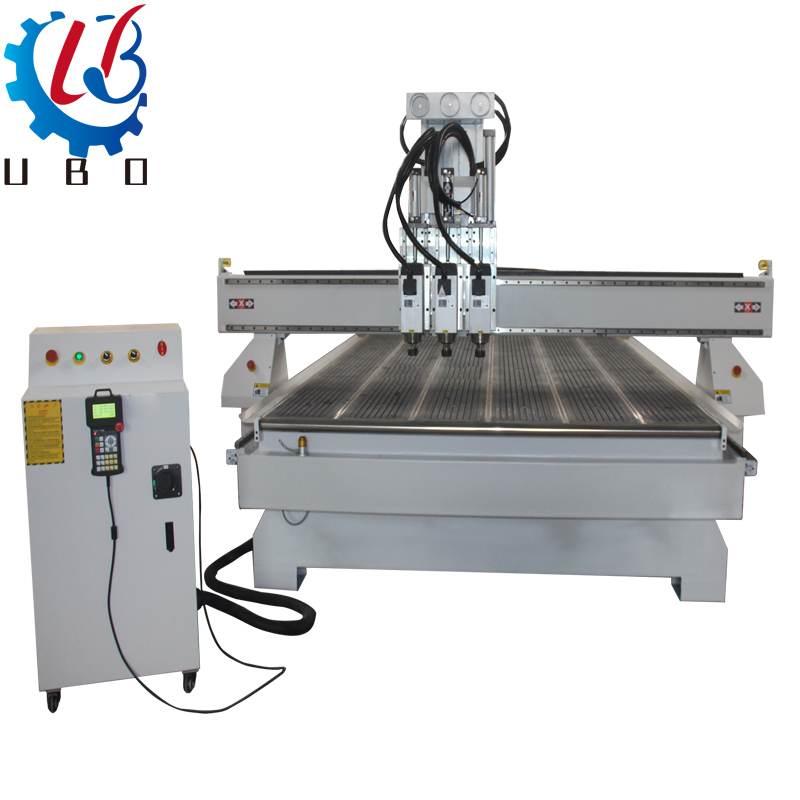

Multi Heads Pneumatic 1325 Pneumatic Atc Woodworking Cnc Router Tools Changer Wood Cutter Machine

1) Multi-head automatic tool change with three air cooling spindle, much more easy change tools ,and can save time to improve efficient.

2) High temperature tempering treatment, welded steel tubeT type machine bed and T type gantry, high rigidity, bearing strength better..

3) Emergency stop button, ensuring the operation safe.

4) Dual motor driver for Y-axis, moving much more stably and powerful.

5) Break points,power off memory way,ensuring the memory function,can continue processing if cutters break or next day working.

6) Intelligent protecting the working table, to prevent the damage by wrong operation. Also can prevent the crush caused by the design working area larger than actual working area.

1. Mould: wood,wax, wood, gypsum,foams,wax

2. Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

3. The wood products: voice box, game cabinets, computer tables, sewing machines table,instruments.

4. Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti bate board, epoxy resin, ABS, PP, PE and other carbon mixed compounds.

5. Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic and soft metals such as copper engraving and milling process.

|

Descriptions |

Parameters |

| Model | UW-1325P-3 |

| Working area | 1300*2500*200mm (Customizable) |

| Table | Vacuum table with 5.5kw/380V pump,super adsorption |

| Spindle | Changsheng/HQD air cooling spindle 4.5kw*3 |

| Inverter | Four in one inverter, pre start |

| Motor and driver | Leadshine 1.3KW servo motor and driver |

| Control system | Weihong control system with a big screen |

| X, Y axis | X, Y axis adopt 1.5m helical rack |

| Z axis | TBI ball screw on Z axis |

| Linear rail | X, Y, Z axis adopt 25 linear rail |

| Reducer | France Motovario reducer |

| Oil lubrication system | Automatic oil lubrication system |

| Dust collector | 5.5kw/380V dust collector with two bags |

| Auto unloading | Automatic forward push material + secondary dust removal after processing |

| Voltage | Three phase 380V /50-60Hz (Customizable) |

| Machine body | Heavy duty body structure, sealing metal plate structure with thick gantry |

| Machine size | 3600*2200*1950mm |

| Net weight | 2600kg |

1. Service before order: our salesman will try to know more about your real requirements , including the max working size, main processing materials and the thickness , then can help you choose the suitable machine.

2. Service during production : we will send the production the machine pictures for customer in time , customer can know more the detailed machine parts.

3. Service before shipping : the machine parts will be installed and tested by our professional. technician, send the test video according to customer’s processing materials for customer confirmations.

4. Service after shipping : we will check when the machine arrive your sea port or the approximate arrival date, so that the customer can know the arrival date and to prepare to pick the machine up

5. Service of warranty : we guarantee the machine for 2 Years, some machine parts ( quality problems ) can be free charge to replace it within warranty.

We are the manufacturer and we have 10 years factory experience. All machines are produced by ourself , quality can be trusted, and also we have professional engineer team to serve you. We know how to fix the problem in each parts easliy. If you interest, welcome to visit to our factory.

For standard machines, it would be about 7-10 working days. For customized machines according to your specific requirements, it would be about 15-20 working days.

You can pay 30% deposit first, then we will start to make production. Once the machine is ready , we will send pictures and video to you, and then you can finish the banlance payment. Finally, we will pack machine and arrange delivery for you as soon as possible.

We offer the service from you got the machine, including how to install the machine, how to use machine, how to let machine work. and so on. Usually we will teach you how to do by email or by skype. Our engineers have many years of experience for cnc machine service. They can speak good English , so he can slove the problem professionally.