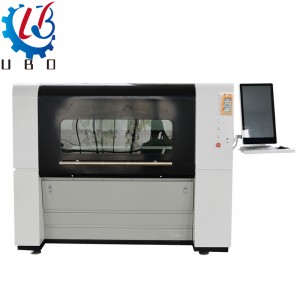

Metal Cnc Fiber Laser Cutter Laser Cutting Machine For Iron Steel Aluminum Copper Plate Sheet With Rotary Device

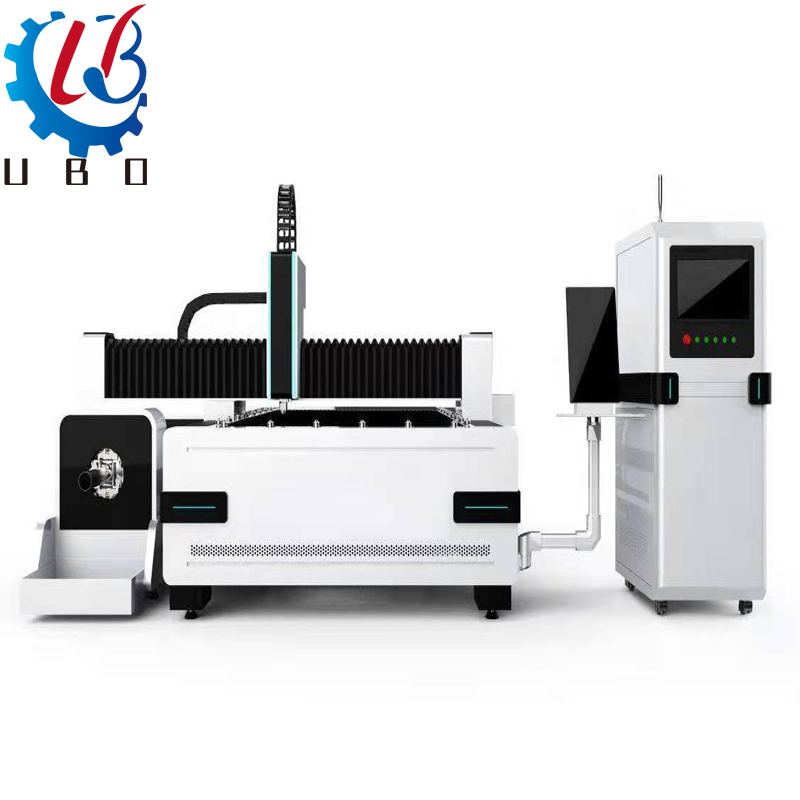

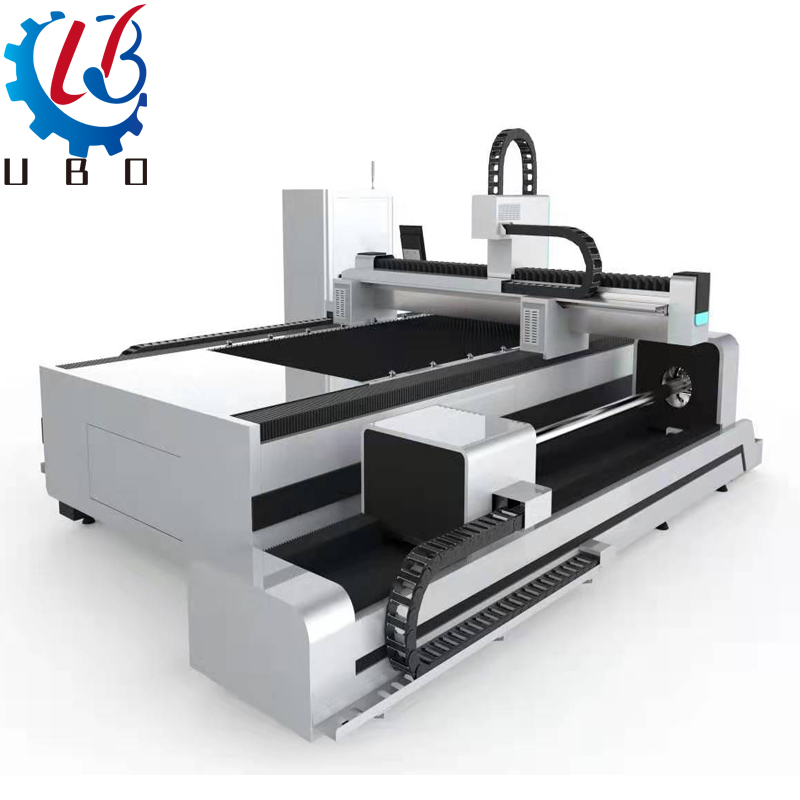

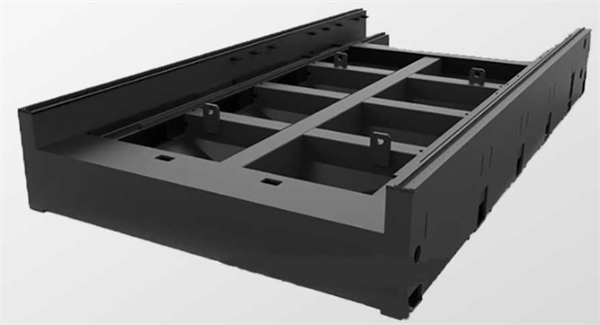

1. High-quality bed, the bed is heavier, quenching treatment, effectively offset the stress. And can maintain stability when the equipment is running at high speed.

2. Aviation aluminum gantry, not only can meet the mechanical strength, but also lighter, reducing the vibration of equipment operation. One-piece casting molding can further improve the processing schedule.

3. The three-axis full dust-proof design can effectively reduce dust pollution, thereby increasing the operating life and operating progress.

4. The multi-faceted design of the loading and unloading auxiliary wheel not only effectively reduces the physical expenditure, but also effectively reduces the collision and damage to the equipment.

5. The central smoke removal design, the smoke and dust generated during cutting are discharged to the outside through the central flue, which effectively reduces the pollution of indoor air, and more humanely protects the operator from inhaling dust particles.

6. The serrated tabletop design can better improve the strength of the tabletop and improve the cutting effect.

7. The rotating shaft with independent feeding saves labor and effort. The equipment is more versatile, not only can cut flat metal plates, but also can cut round pipes and square pipes, truly achieving multiple uses in one machine.

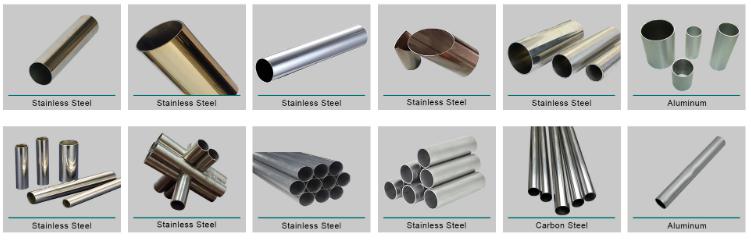

Applicable materials for laser cutting machine for metal

Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet,Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet,Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Application Industries

Fiber Laser Cutting Machine is widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters,Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & CabinetsProcessing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts,Nameplates, etc

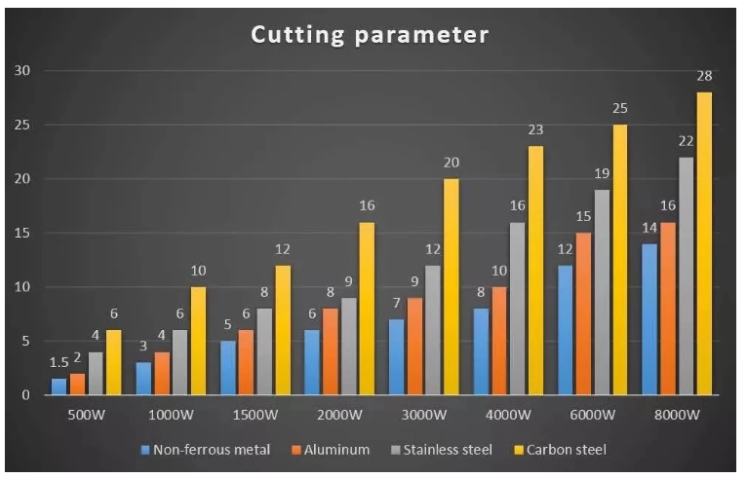

Cutting ability

specially used in cutting 0.5~14mm carbon steel,0.5~10mm stainless steel,galvanized plate

lectro-Galvanized Steel,silicon steel,0.5~3mm aluminium alloy,0.5~2mm brass and red copper etc thin metal sheet (The laser brandcan be customized, power optional from 1000w-6000w )

| Model | UF-C3015R |

| Working area | 3000*1500mm |

| Miximum length of pipe(Options) | 3000mm(or)6000mm |

| Limits of pipe(Customized) | Round tube:Φ20mm~Φ120mm; Square tube :Φ20mm~210mm; Circular tube: Φ20mm~Φ350mm; |

| Laser type | Fiber laser generator |

| Laser power(optional) | 1000~4000W |

| Transmission system | Double serve motor &gantry&rack&pinion |

| Maximum speed | ±0.03mm/1000mm |

| Pipe cutting system(optional) | yes |

| Maximum speed | 60m/min |

| Maximum accelerated speed | 1.2G |

| Position accuracy | ±0.03mm/1000mm |

| Reposition accuracy | ±0.02mm/1000mm |

| Graphic format supported | CAD,DXF(etc) |

| Power supply | 380V/50Hz/60Hz |

1.Purchase Service

Foster LASER have a specialized and efficiency working team.If you are new on the laser machine, we will give you specialized suggestion of whole work .

2. Shipping Service

Foster LASER have a specialized and independent department which just for arranging shipping for buyer's goods .The workers are knowing T/T,L/C Items well.all Exported documents could be made perfectly .

3.Installation Service

Installation Services are available with all Foster LASER Company machines.We will dispatch technician to The Buyer's factory to installation and preparation of machines.

4.Clients Training Service

Foster Laser advises the buyer could send own technician come to our factory to learn how to operate machines.Foster LASER Company technician will teach and train the learners hand by

hand till he can operate machine by himself.

5.After Sales Service

Foster LASER machines guarantee time is two years, except consumables parts;

A1:We will send you the teaching video of the machine and 24-hour online service,we also support free training service, engineers can train your workers for free in our factory for 1-3 days,if you want door-to-door service,We can arrange local service in 48 hours

A2:Please tell me your

1) Your materials

2) Max size of your material

3) Max cut thickness

4) Popular cut thickness

A3:We support the production visualization service. The sales department who responds to your inquiry for the first time will be responsible for your follow-up work. You can contact him /her to go to the factory to check the production progress of the machine, or send you the sample pictures and videos you want. We support free sample service.

A4:Different customers, different requirements, and many different laser power can be optional, that's why we list the price not include fiber source parts.

A5:

1) We have detailed user manual with pictures and CD,you can learn step by step.And our user manual update every month for your easy learning if there is any update on machine.

2) If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. We can provide team viewer/Whatsapp/Email/Phone/Skype with cam till all of your problems finished.We can also provide Door service if you need.

CAST-IRON BED, ANTI-VIBRATION, STABLE, NO DEFORMATION

* The main frame adopts the gantry structure welded by all steel plates to ensure the long-term stability without deformation

* The bed is annealed at high temperature in a large annealing furnace

* The bed is formed by imported gantry milling once

* Using gantry rack double guide rail, double servo drive structure

* Improve the stability and rigidity of the Y-axis beam

* Ensure the high precision and high dynamic performance of Y-axis beam movement

* Y-axis beam runs smoothly at high speed, greatly reducing gas consumption

Raycus Fiber Laser

1.Electro-optical conversion efficiency up to 30%.

2. They are excellent beam quality, high energy density, and reliability, a wide modulation frequency;

3. 100,000 hours of lifetime, free maintenance; Low energy consumption, only 20%-30% of the traditional CO2 machine.

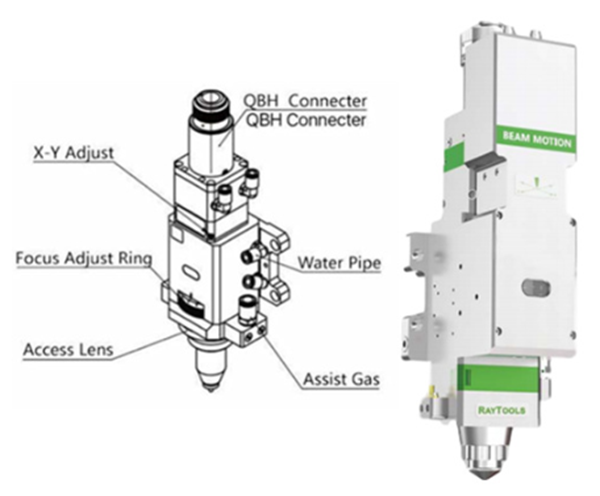

RAYTOOLS AUTO-FOCUS LASER CUTTING HEAD

* AUTOFOCUS: Through the built-in drive unit of the servo motor, the focusing lens is driven by the linear mechanism to automatically change the position in the focusing range. The user can set continuous zoom through the program to complete the rapid piercing of the thick plate and automatic cutting of different materials. *EFFICIENT: Reading the saved cutting parameters through the operating system can quickly change the focus position of the laser head, eliminating manual operation and improving efficiency by 30% *STABLE: Unique optical configuration, smooth and efficient airflow design and dual water-cooled design make the laser head work stably for a long time

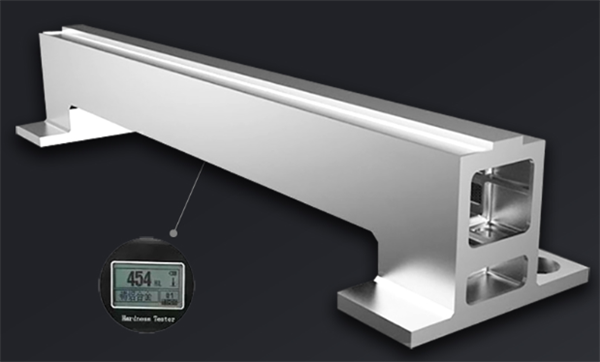

Cast Aluminum Integrated Beam

The whole structure is made of steel die casting, which is finished after artificial aging and solid solution treatment, so that the beam rigidity, surface quality, integrity and other performance are all excellent. At the same time, it has the characteristics of high flexibility, which can achieve high-speed cutting of all kinds of graphics under the condition of satisfying the precision.

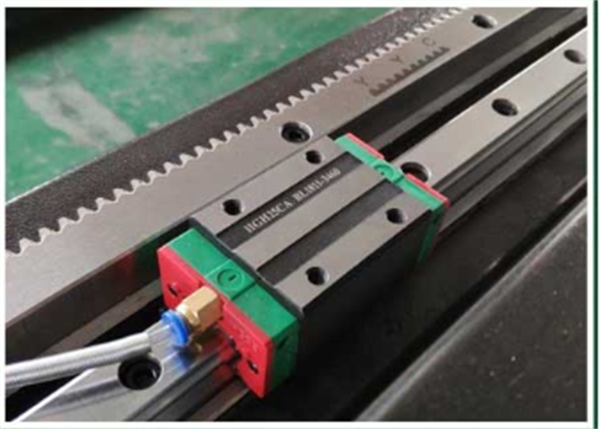

GEARS, RACKS, GUIDES

* The guide rail and rack are calibrated by a precision collimator with an accuracy of ±0.02mm

* Using Taiwan YYC rack, grinding on all sides. And there is a positioning pin design to prevent the rack from shifting

* Using Taiwan HIWIN guide rail, and use oblique pressure block design to prevent displacement of guide rail

Japan Yaskawa servo motors and driver.

High-precision ASG geared motor imported from Japan

Water cooling control system:

The fiber laser and laser head even working at high temperature can be cooled quickly to ensure that the laser machine has stable power, high efficient and fast operation.Exclusive no water warning and automatic protection system, if there's no water or the water flows in opposite direction, there'll be alarm prompt and stop working,can protect the working life of fiber laser effectively.

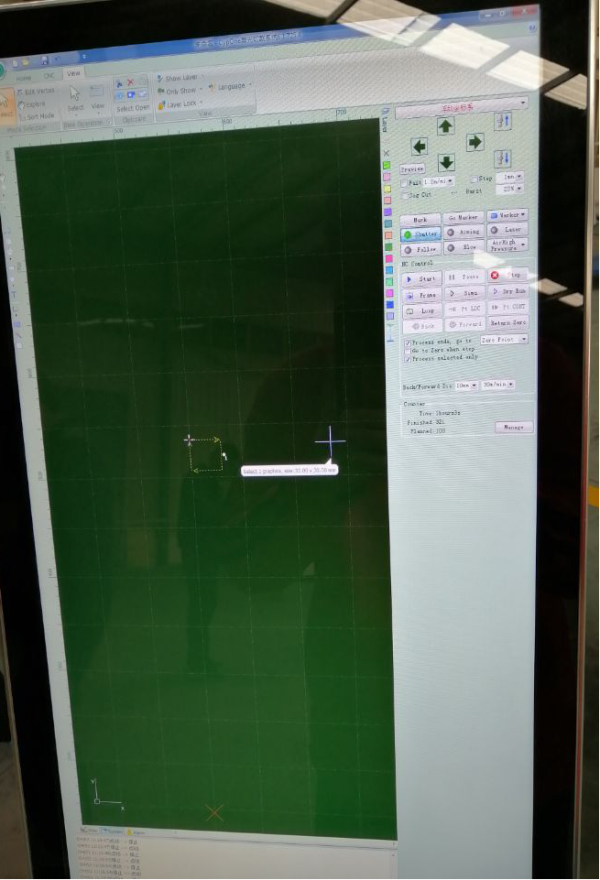

Cypcut professional cutting system.The operating system can realize intelligent layout of graphics cutting and support the import of multiple graphics, optimizing cutting orders automatically, searching edges smartly and automatic positioning. Control system adopts the best logic programming and software interaction, provides stunning operation experience, effectively enhancing the utilization of sheet metal and reducing waste. Simple and fast operation system, efficient and accurate cutting instructions, effectively improve the user experience.

Rotary device