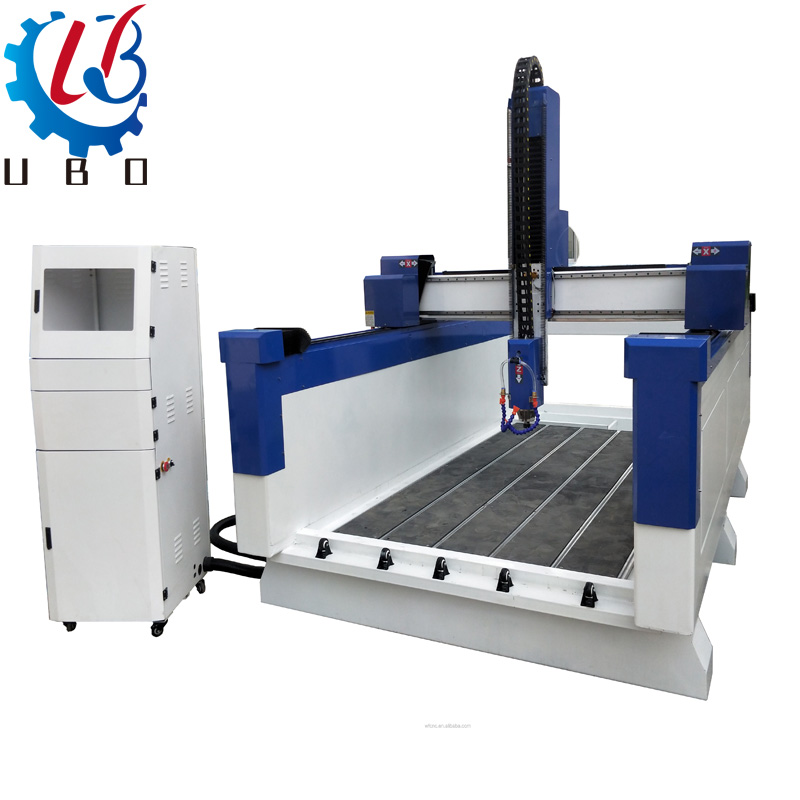

Manufacturing Companies for Precision Cnc Router - Heavy duty Wooden router 1325 cnc engraving cutting machine – UBO

Manufacturing Companies for Precision Cnc Router - Heavy duty Wooden router 1325 cnc engraving cutting machine – UBO Detail:

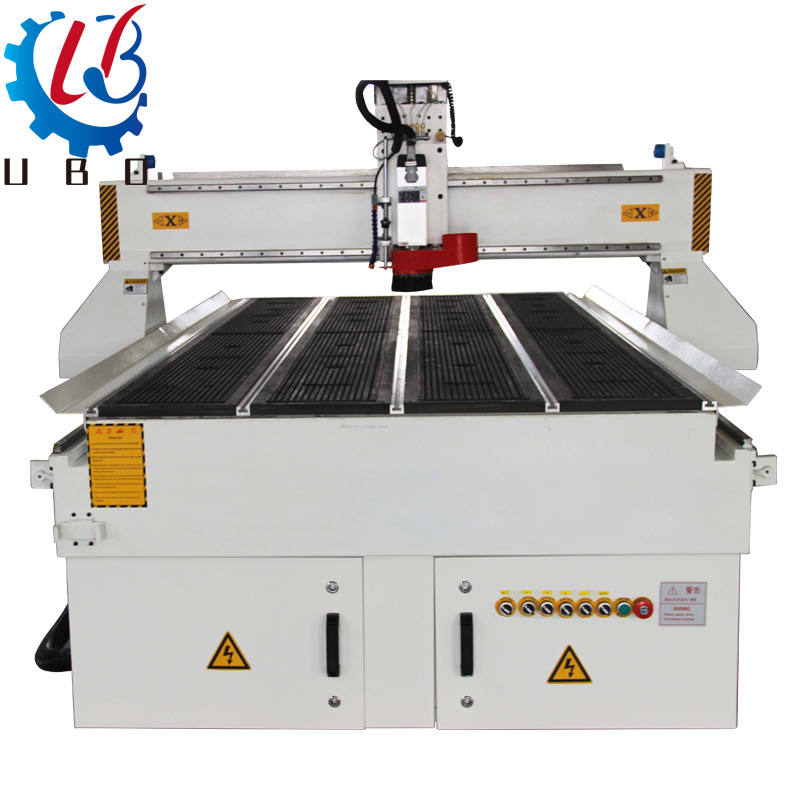

1. Imported Taiwan HIWIN square guide rails, longer life and smooth moving,

2. Chinese best brand Air cooling spindle with 18000rpm,

3. Helical rack gear transmission,which can ensure faster speed,higher efficiency,stronger power,longer lifetime,and it makes the machine more stable.

4. With off line DSP control system, It can support offline operation. easy to operate.

5. Standard configured with leadshine servo motor or stepper motor FL118 and YAKO 2811 big driver,very powerful.

For option,we can change toJapan YASKAWA servo or Taiwan DELTA servo motors and drivers.

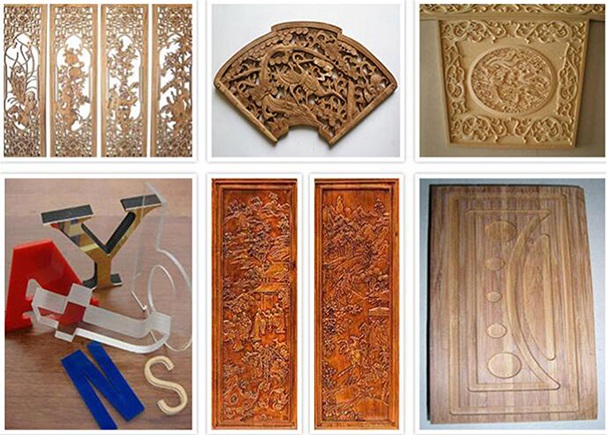

1.wood Furniture products: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows,voice box, game cabinets, computer tables, sewing machines table, instruments.

2.others sheets processing: plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti bate board, epoxy resin, ABS, PP, PE and other carbon mixed compounds.

3.Decoration industry: Acrylic, PVC, artificial stone, organic glass, plastic and some soft metals such as copper, alum- inum plate engraving and milling process.

| Model | UW-1325T |

| X axis travel | 1300mm |

| Y axis travel | 2500mm |

| Z axis travel | 250mm |

| Processing accuracy | ±0.05mm |

| Repeat positioning accuracy | ±0.05mm |

| Tool magazine | In-line tool magazine 12 tools |

| Repeat positioning | 0.05mm |

| Operating System | DSP Control System |

| Guide rail | Taiwan square rail |

| Running speed | 55m/min |

| Carving speed | 30m/min |

| Software operating environment | Windows2000/XP/98 |

| Engraving instruction | G-code/HP-GL |

| Spindle | HQD 4.5kw 18000r/min air-cooled spindle |

| Drive motor | Leadshine servo motor and driver |

| Power supply | 380V 50Hz |

Pre-Sales Service

1.We have many exhibitions very year, hundreds of clients was coming to our booth for further communication.

2. 24-hours online Inquiry and consulting support.

3.Support sample testing .

4.We welcome you to visit our factory.

After-Sales Service

1. Training how to install the machine, training how to use the machine online.

2.Engineers available to clients’ factory for training.

3.Guarantee for two year

4.24-hour technical support by email or calling

5.User-friendly English manual for machine using and maintaining

6.Free technician training for customers.

Main Parameters:

Q1. How to choose a suitable machine?

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience.

Other kinds of payment we can consider if acceptable for us.

Q2. How long time will need for my machine to delivery?

For standard machines, it would be about 7-10 days. For customized machines according to your specific requirements, it would be about 15-20 working days.

Q3. How can I get the machine ,how to order ?

After we confirm all details ,then You can pay 30% deposit according the Proforma invoice, then we will start to make production. Once the machine is ready , we will send pictures and video to you, and then you can finish the banlance payment. Finally, we will pack machine and arrange delivery for you as soon as possible.

Q4. How to use the machine after receving the machine

Firstly , when you got machine , you need to contact with us ,our engineer will together with your to deal with it ,secondly ,we send user manuals and

CD to you before you get the machine ,Thirdly Our professional technician online teach you until you can use it well by yourself.

Q5.About the Payment terms,how to pay money ?

1) T/T, means international bank transfer. 30% deposit, we produce the machine for you. 70% before shipping.

2)L/C at sight

3)D/P at sight

Product detail pictures:

Related Product Guide:

In order to give you convenience and enlarge our business, we also have inspectors in QC Team and assure you our best service and product for Manufacturing Companies for Precision Cnc Router - Heavy duty Wooden router 1325 cnc engraving cutting machine – UBO , The product will supply to all over the world, such as: Eindhoven, Slovakia, Colombia, Our mission is "Provide Goods with Reliable Quality and Reasonable Prices". We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.