Factory Free sample Diy Mini Cnc Router - 4 Axis Foam Carving Sculpture Cutting Machine/4 Axis Cnc Milling Router Machine – UBO

Factory Free sample Diy Mini Cnc Router - 4 Axis Foam Carving Sculpture Cutting Machine/4 Axis Cnc Milling Router Machine – UBO Detail:

1. It adopts well-known 9.0KW HQD spindle, which is famous brand and has many after service department all over the world. adopts air cooling spindle, no need water pump, it is very convenient to use.

2. with high-performance Japan YASKAWA servo motor, the machine can work in high precision, the servo motor runs smoothly, no vibration phenomenon even in the low speed, and it has a strong ability of overload.

3. The linear automatic tool changer system which contains 6 or 8 pieces of cutting tools and saw cuttting are controlled by CNC Syntec Control system.The tools can be changed very quickly and reliably.

4. Break point memory, continuing carving after power outage, forecasting processing time and other functions.

5. It is compatible with Type3 / Artcam / Castmate, and other CAD / CAM design software.

1)Foam processing of automotive stamping dies, casting of wood molds, automotive interiors, engineering plastic materials, and various non-metal processing

2) Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

3) Wood mold processing center: Casting wood mold, automotive inspection tool processing, automotive interiors, engineering plastic materials and other non-metallic processing.

| Model | UB-L1530L |

| Machine | large cnc wood foam eps router milling machine |

| X,Y,Z axis working area | 2000*4000*600mm |

| X,Y movement | Rack and pinion |

| Z movement | Ball screw transmission |

| Guide | Taiwan HIWIN/PMI 20 square rails(round rails optional) |

| Max idling speed | 40000mm/min |

| Max engraving speed | 23000mm/min |

| Spindle power | 9kw watercooling/aircooling (customized) |

| Spindle speed | 18000-24000rpm |

| inverter | Delta 11kw |

| Drive motors | Yaskawa Servo motors and drviers |

| drivers | Leadshine |

| Control system | Syntec control system |

| Working voltage | 220V/380V or customized |

| Command code | G code |

| software | Artcam,type 3,etc |

| collet | ER 25-32 |

| Standard equipment included | 1.automatic oil injection system 2.Tool sensor 3.vacuum table, 5.5kw vacuum pump |

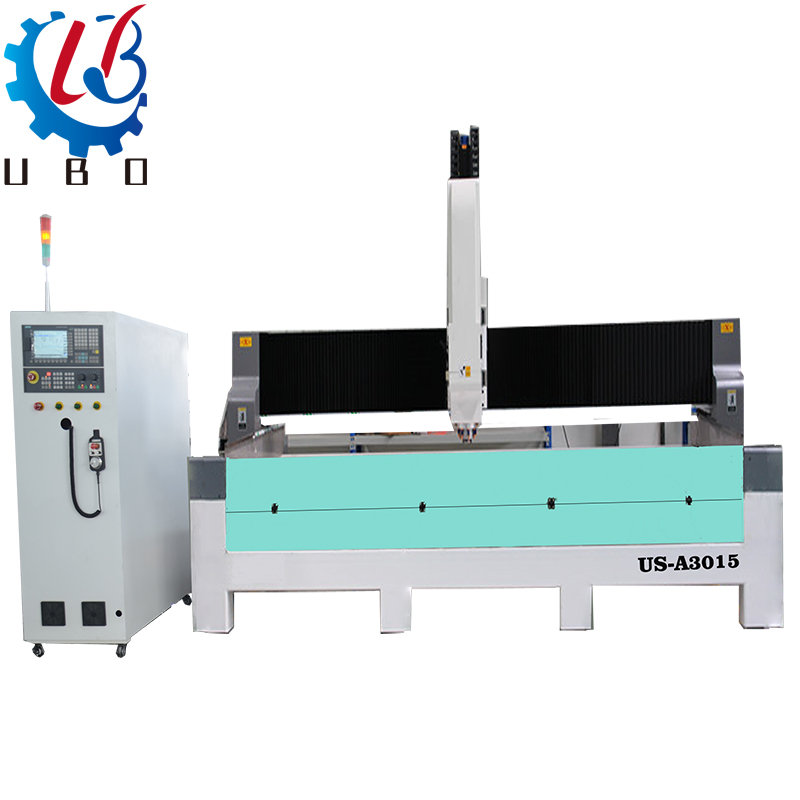

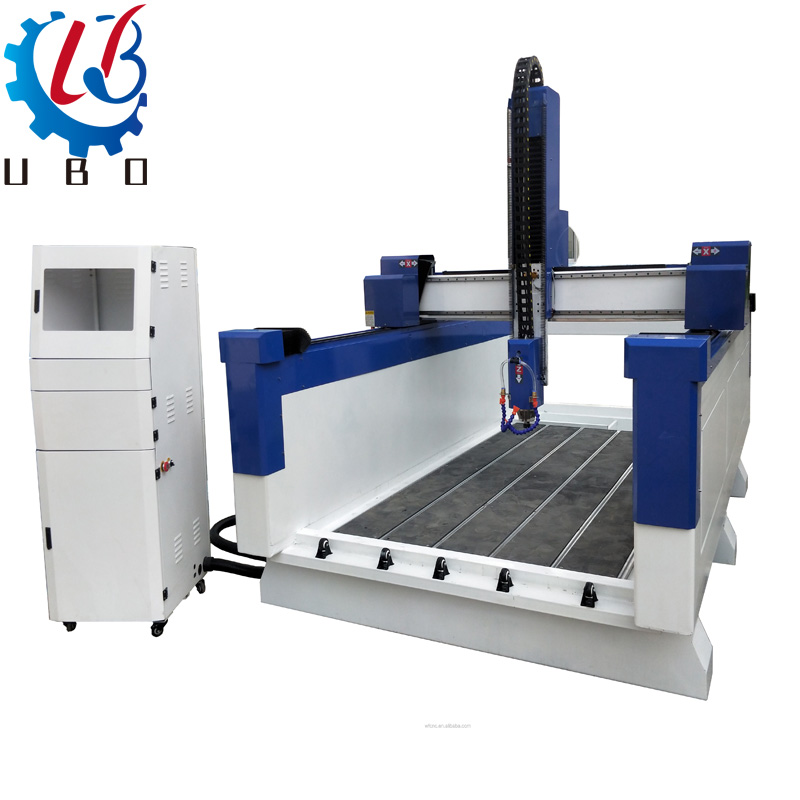

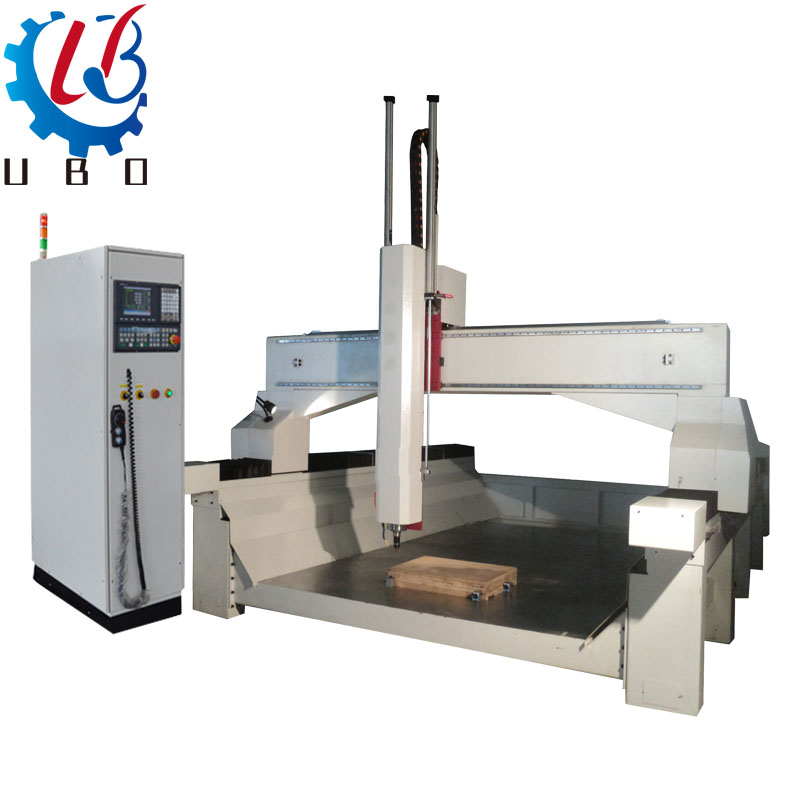

Product detail pictures:

Related Product Guide:

Innovation, good quality and reliability are the core values of our enterprise. These principles today extra than ever form the basis of our success as an internationally active mid-size organization for Factory Free sample Diy Mini Cnc Router - 4 Axis Foam Carving Sculpture Cutting Machine/4 Axis Cnc Milling Router Machine – UBO , The product will supply to all over the world, such as: Morocco, Bhutan, Botswana, "Make the women more attractive "is our sales philosophy. "Being customers' trusted and preferred brand supplier" is the goal of our company. We are strict with every part of our work. We sincerely welcome friends to negotiate business and start cooperation. We hope to join hands with friends in different industries to create a brilliant future.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!