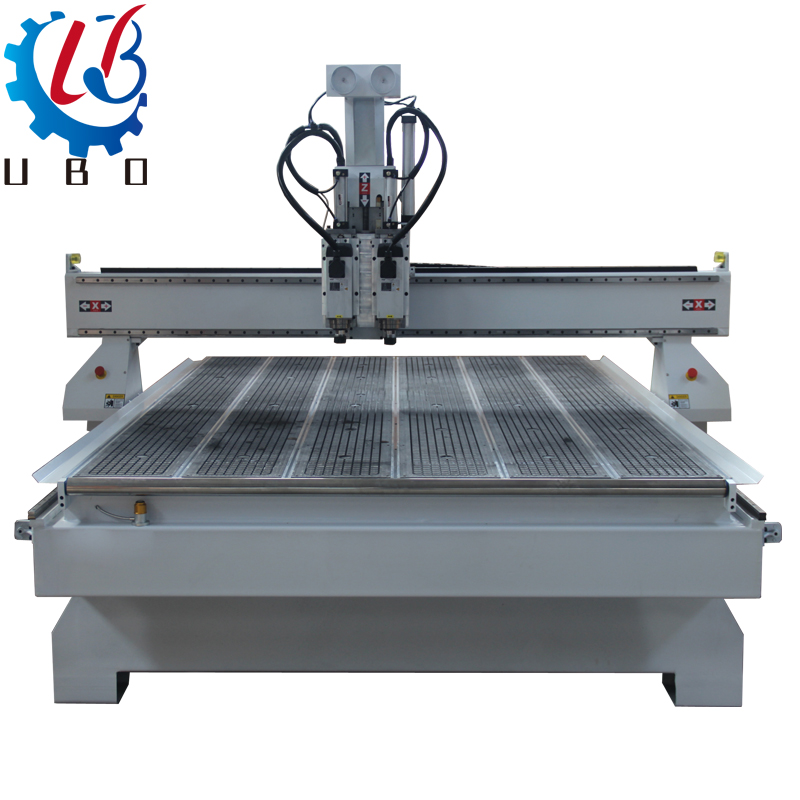

China Cheap price 4×8 3 Axis Wood Cnc Router - Double Spindle Head Pneumatic Tool Changer 1325 Cnc Wood Carving Machine / Mdf Cnc Router – UBO

China Cheap price 4×8 3 Axis Wood Cnc Router - Double Spindle Head Pneumatic Tool Changer 1325 Cnc Wood Carving Machine / Mdf Cnc Router – UBO Detail:

1) Double air cooling spindle, like simple auto changer tool.

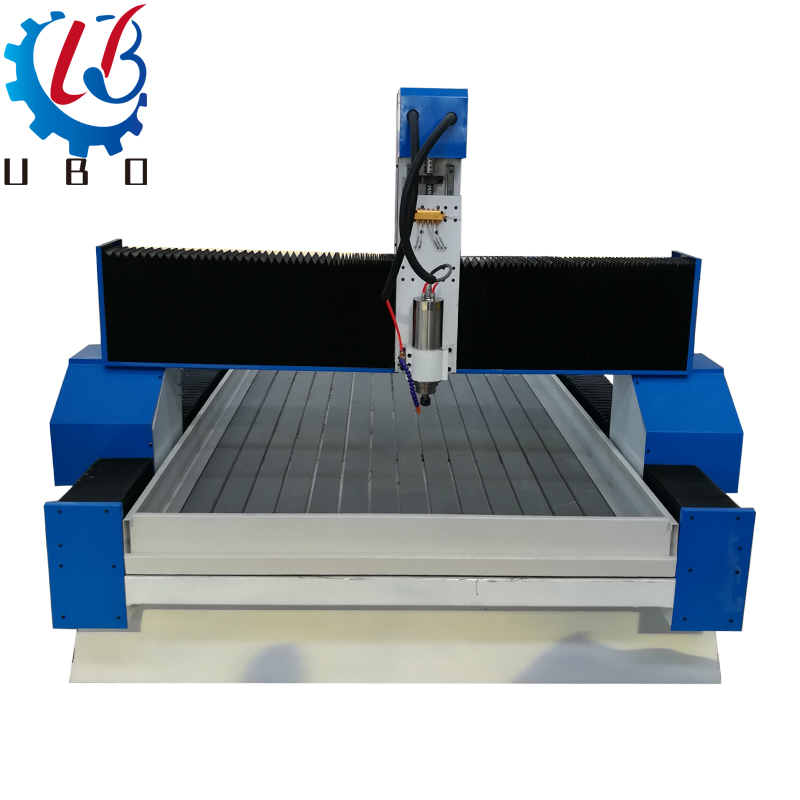

2)Taiwan TBI balls screws, HIWIN square guide rails, high precision, large load bearing and stable running.

3) Gantry-travelling, sturdy, reliable and stable, non-deforming, high locating accuracy.

4) Y axis use servo/stepper motor drive, select matching to ensure smooth movement.

5) DSP control system, with U disk available and not need computer (can be completely off-line operation. ), it provides high independence and great convenience for operation.

6) Unique ability to save several point of origin on several workpieces.

7) No engraving saw-tooth, smooth undersurface, legible contour, by high-power spindle.

8) Auto seeking original point system, a good way to improve the working effeciency.

9) Large compatibility of drawing software, such as Type3, artcam and other CAD or CAM.

10) Vacuum table can support materials of different sizes effectively.

* Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

* The wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

* Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti-Bate board, epoxy resin, ABS, PP, PE, PEHD and other carbon mixed compounds.

* Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

|

Descriptions |

Parameters |

| Model | UW-1325P-2 |

| Working area | 1300*2500*200mm (Customizable) |

| Table | Vacuum table with 7.5kw/380V pump,super adsorption |

| Spindle | Changsheng/HQD air cooling spindle 6kw*3 |

| Inverter | Four in one inverter, pre start |

| Motor and driver | Leadshine 1300W servo motor and driver |

| Control system | Weihong control system with a big screen |

| X, Y axis | X, Y axis adopt 1.5m helical rack |

| Z axis | Z axis adopt TBI-2510 ball screw |

| Linear rail | X, Y, Z axis adopt 25 linear rail |

| Reducer | France Motovario reducer |

| Oil lubrication system | Automatic oil lubrication system |

| Dust collector | 5.5kw/380V dust collector with two bags |

| Auto unloading | Automatic forward push material + secondary dust removal after processing |

| Voltage | 380V (Customizable) |

| Machine body | Heavy 3.5m machine body, sealing metal plate structure with thick gantry |

| Machine size | 3600*2200*1950mm |

| Net weight | 2600kg |

Product detail pictures:

Related Product Guide:

Our target should be to consolidate and improve the high-quality and repair of current goods, in the meantime regularly produce new solutions to meet unique customers' needs for China Cheap price 4×8 3 Axis Wood Cnc Router - Double Spindle Head Pneumatic Tool Changer 1325 Cnc Wood Carving Machine / Mdf Cnc Router – UBO , The product will supply to all over the world, such as: Marseille, Iran, Atlanta, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.