Auto edge banding machine

12 Functions:

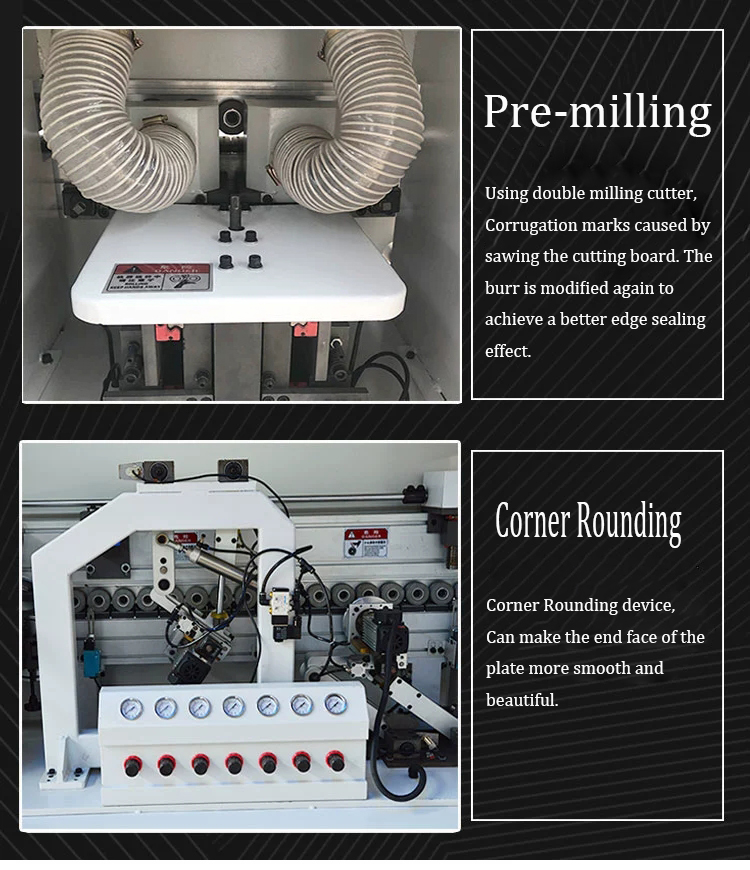

Pre-milling,

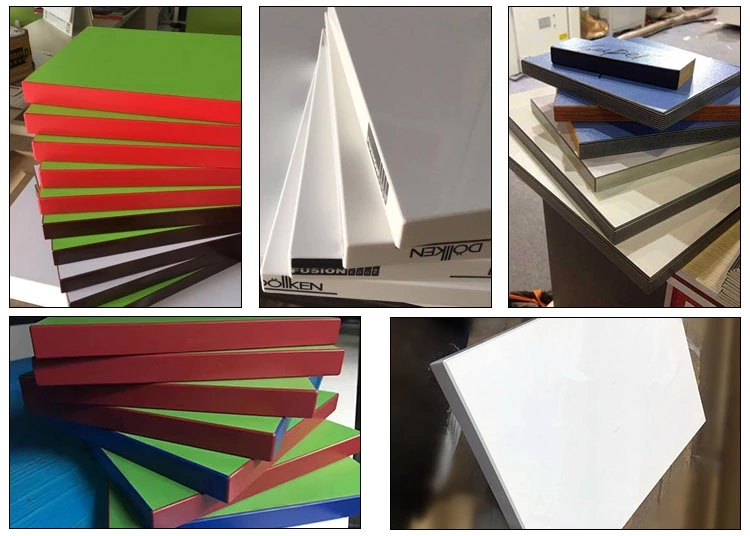

pre-heating,

gluing,

edge bonding,

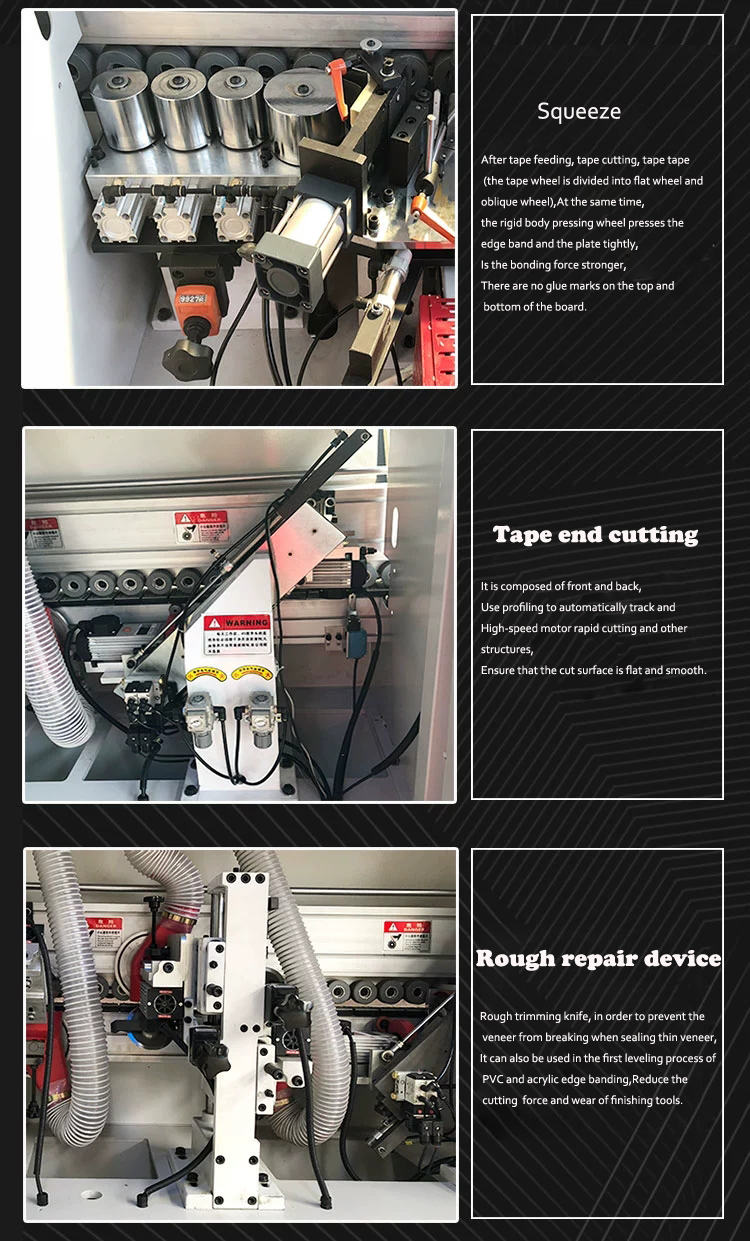

pressing,

belt cutting,

front and back flush,

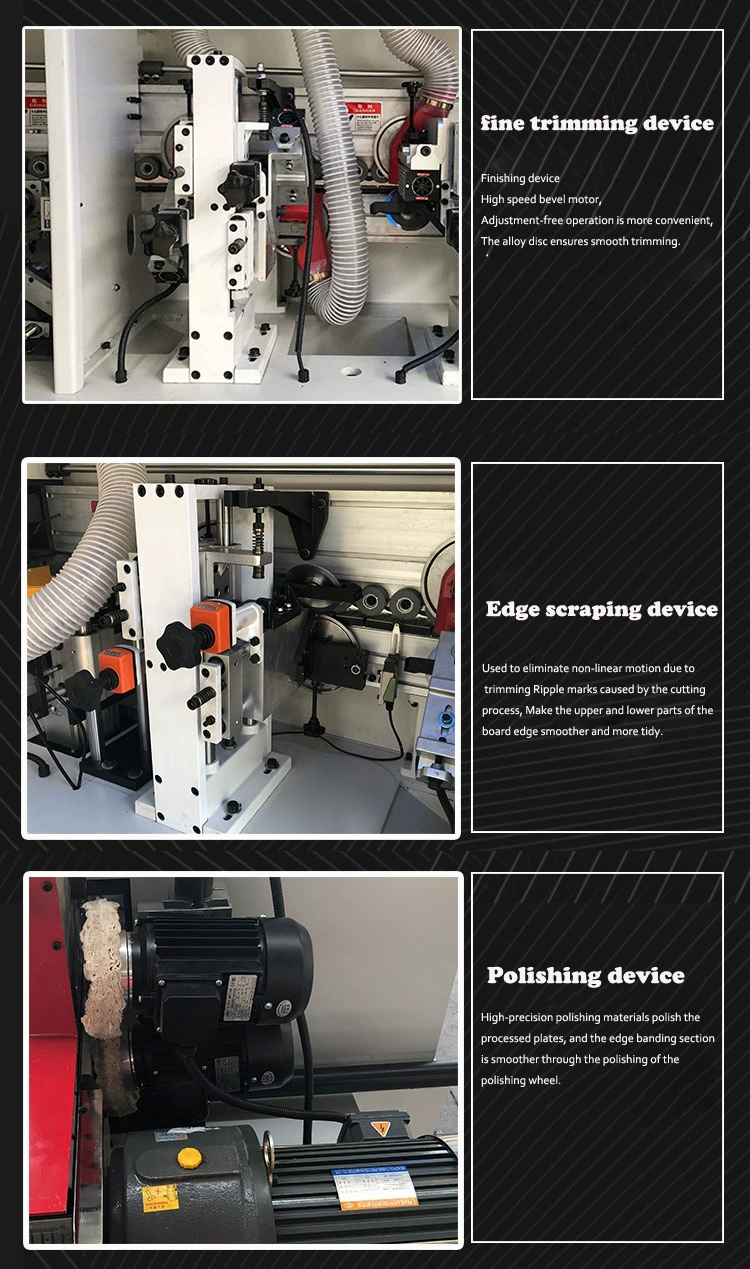

rough trimming,

fine trimming,

Corner round,

scraping,

Polishing

| Item | Model: | UB-F890 |

| 1 | Min Plate width | 40mm |

| 2 | Min plate Length: | 60mm |

| 3 | Edge band width: | 10-70mm |

| 4 | Edge band thickness: | 0.3-3.5mm |

| 5 | Conveyor Speed : | 18m/min |

| 6 | Plate thickness: | 10-60mm |

| 7 | Working pressure: | 0.6-0.8Mpa |

| 8 | preheating | power: 0.3 kw |

| 10 | transmission power: | 0.55 kw |

| 11 | conveyor belt motorpower: | 1.5 kw |

| 12 | Polishing MotorPower: | 0.18 kw * 2 |

| 13 | Heating Power: | 1.8 kw |

| 14 | Roughing Motor Power: | 0.75 kw * 2 18000r/min.300hz |

| 15 | flush Motor Power: | 0.55 kw * 2 12000r/min.200hz |

| 16 | finishing motor power: | 0.75 kw * 2 18000r/min.300hz |

| 17 | Total Power: | 16kw |

| 18 | Overall Size: | 6500*1000*1600mm |

| 19 | Total Weight: | 2500kg |

1. The body is made of 18mm steel

2. Conveyor belt guide rail is made of HT260 material,

durable and smooth without deformation

3. Transmission motor adopts Taiwan Dongli brand

4. High speed motor all adopt well-known and reliable

brand Tianjin safety motor efficient and stable

5. Unified guide rail adopts Taiwan brand, stable and

durable

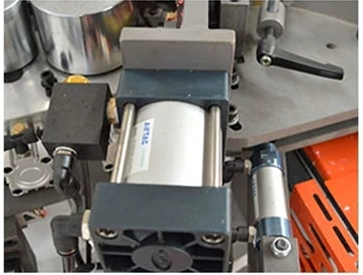

6. Air circuit system, Taiwan Airtac solenoid valve,

T9aiwan AirTAC head cylinder with magnetic ring

Induction switch, Taiwan AirTAC pressure regulating

valve, Yili oil-water separator

7. Electrical system, Drissie/Chint: air switch,

contactor, Omron travel switch,

8. The touch screen adopts Taiwan Delta PLC control

system

9. The inverter adopts the famous brand Jiale